Best Price for Taper Bushings Eu Standard - Taper Bushings per European Standard, in Cast GG20 or Steel C45 – GOODLUCK

Best Price for Taper Bushings Eu Standard - Taper Bushings per European Standard, in Cast GG20 or Steel C45 – GOODLUCK Detail:

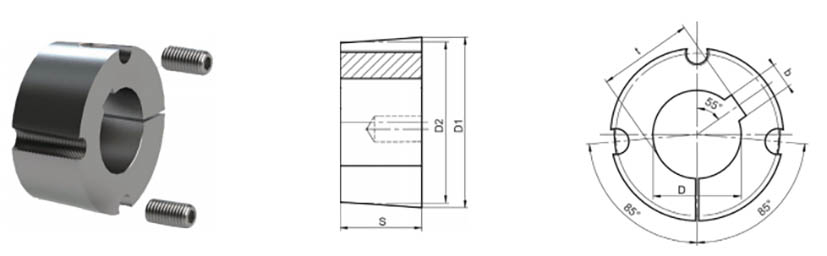

Cast iron: GG20

Tools for tighten: Allen wrench 1/8″

Screw Specification: 1/4-20BSW X1/2

Screws Quantity: 2

Transmissible torque: 136Nm

Screw tightening torque: 5. 6Nm

Bore In Metric

|

Product Model |

D1 |

D2 |

s |

D(G7) |

b |

Js9 |

t |

Weight (Kg) |

|

1008-8MM 1008-9MM 1008-10MM |

35.2 |

33.73 |

22.3 |

8 9 10 |

2 3 3 |

±0.0125 |

D+1 D+1.4 D+1.4 |

0.13 0.12 0.11 |

|

1008-11MM 1008-12MM 1008-14MM 1008-15MM 1008-16MM 1008-17MM 1008-18MM 1008-19MM 1008-20MM 1008-22MM |

11 12 14 15 16 17 18 19 20 22 |

4 4 5 5 5 5 6 6 6 6 |

±0.015 |

D+1.8 D+1.8 D+2.3 D+2.3 D+2.3 D+2.3 D+2.8 D+2.8 D+2.8 D+2.8 |

0.11 0.11 0.11 0.11 0.1 0.1 0.09 0.09 0.07 0.07 |

|||

|

1008-24MM 1008-25MM |

24 25 |

8 8 |

±0.018 |

D+1.3 D+1.3 |

0.06 0.06 |

Bore In Inches

|

Product Model |

D1 |

D2 |

s |

D(G7) |

b |

t |

Weight (Kg) |

|||||||

|

1008-3/8 1008-7/16 1008-1/2 |

1.328″ |

0.878″ |

3/8″ 7/16″ 1/2″ 9/16″ 5/8″ 11/16″ 3/4″ |

l/8″ 3/16″ |

D+l/16″ D+l/16″ D+l/16″ D+3/32″ D+3/32″ D+3/32″ D+3/32″ |

0.11 0.11 0.11 0.11 0.1 0.1 0.1 |

||||||||

|

1008-9/16 1008-5/8 1008-11/16 1008-3/4 |

1.386″ |

|||||||||||||

|

1008-13/16 1008-7/8 1008-15/16 1008-1 |

13/16″ 7/8″ 15/16″ 1″ |

1/4″ |

D+l/8″ D+l/8″ D+l/8″ D+l/16″ |

0.08 0.07 0.07 0.06 |

||||||||||

Cast iron: GG20

Tools for tighten: Allen wrench 1/8″

Screw Specification: 1/4-20BSW X1/2

Screws Quantity: 2

Transmissible torque: 147Nm

Screw tightening torque: 5. 6Nm

Bore In Metric

|

Product Model |

D1 |

D2 |

s |

D(G7) |

b |

Js9 |

t |

Weight (Kg) |

|

1108-9MM 1108-10MM |

38.32 |

36.92 |

22.3 |

9 10 11 12 |

3 4 |

±0.0125 ±0.015 |

D+1.4 D+1.4 D+1.8 D+1.8 D+2.3 D+2.3 D+2.3 D+2.3 D+2.8 D+2.8 D+2.8 D+2.8 D+2.8 |

0.15 0.15 0.14 0.14 0.14 0.13 0.12 0.12 0.12 0.11 0.11 0.11 0.11 |

|

1108-11MM 1108-12MM |

||||||||

|

1108-14MM 1108-15MM 1108-16MM 1108-17MM |

14 15 16 17 |

5 |

||||||

|

1108-18MM 1108-19MM 1108-20MM 1108-21MM 1108-22MM |

18 19 20 21 22 |

6 |

||||||

|

1108-24MM 1108-25MM 1108-26MM 1108-28MM |

24 25 26 28 |

8 |

±0.018 |

D+3.3 D+3.3 D+3.3 D+1.3 |

0.09 0.08 0.08 0.06 |

Bore In Inches

|

Product Model |

D1 |

D2 |

s |

D(G7) |

b |

t |

Weight (Kg) |

|||||

|

1108-3/8 1108-7/16 1108-1/2 |

1.5086″ |

1.4535″

|

0.878″ |

3/8″ 7/16″ 1/2″ 9/16″ 5/8″ 11/16″ 3/4″ |

l/8″ 3/16″ |

D+1/16″ D+1/16″ D+1/16″ D+3/32″ D+3/32″ D+3/32″ D+3/32″ D+1/8″ D+1/8″ D+1/8″ D+1/8″ |

0.15 0.15 0.15 0.14 0.13 0.13 0.12 0.11 0.1 0.09 0.08 |

|||||

|

1108-9/16 1108-5/8 1108-11/16 1108-3/4 |

||||||||||||

|

1108-13/16 1108-7/8 1108-15/16 1108-1 |

13/16″ 7/8″ 15/16″ |

1/4″ |

||||||||||

|

1108-1-1/16 |

1108-1-1/16 |

5/16″ |

D+1/8″ |

0.07 |

||||||||

Cast iron: GG20

Tools for tighten: Allen wrench 3/16″

Screw Specification: 3/8-16BSW x5/8

Screws Quantity: 2

Transmissible torque: 407Nm

Screw tightening torque: 19. 6Nm

Bore In Metric

|

Product Model |

D1 |

D2 |

s |

D(G7) |

b |

Js9 |

t |

Weight (Kg) |

|

1210-9MM 1210-10MM |

47.55 |

44.44 |

25.4 |

9 10 11 12 |

3 4 |

±0.0125 |

D+1.4 D+1.4 D+1.8 D+1.8 |

0.27 0.27 0.27 0.26 |

|

1210-11MM 1210-12MM |

||||||||

|

1210-13MM 1210-14MM 1210-15MM 1210-16MM 1210-17MM |

13 14 15 16 17 |

5 |

±0.015 |

D+2.3 D+2.3 D+2.3 D+2.3 D+2.3 |

0.25 0.26 0.25 0.24 0.24 |

|||

|

1210-18MM 1210-19MM 1210-20MM 1210-22MM |

18 19 20 22 23 24 25 26 28 30 |

6 8 |

±0.018 |

D+2.8 D+2.8 D+2.8 D+2.8 D+3.3 D+3.3 D+3.3 D+3.3 D+3.3 D+3.3 |

0.23 0.23 0.22 0.2 0.2 0.2 0.18 0.18 0.16 0.15 |

|||

|

1210-23MM 1210-24MM 1210-25MM 1210-26MM 1210-28MM 1210-30MM |

||||||||

|

1210-32MM |

32 |

10 |

D+3.3 |

0.14 |

Bore In Inches

|

Product Model |

D1 |

D2 |

s |

D(G7) |

b |

t |

Weight (Kg) |

|

1210-1/2 |

1.872” |

1.75”

|

1″ |

1/2″ |

1/8″ |

D+1/16″ |

0.25 |

|

1210-9/16 |

9/16″ |

3/16″ |

D+3/32″ |

0.24 |

|||

|

1210-5/8 |

5/8″ |

D+3/32″ |

0.24 |

||||

|

1210-11/16 |

11/16” |

D+3/32″ |

0.24 |

||||

|

1210-3/4 |

3/4″ |

D+3/32″ |

0.23 |

||||

|

1210-13/16 |

13/16″ |

1/4″ |

D+1/8″ |

0.22 |

|||

|

1210-7/8 |

7/8″ |

D+1/8′1 |

0.22 |

||||

|

1210-15/16 |

15/16′1 |

D+1/8″ |

0.19 |

||||

|

1210-1 |

1″ |

D+1/8″ |

0.19 |

||||

|

1210-1-1/16 |

1-1/16″ |

5/16″ |

D+1/8″ |

0.16 |

|||

|

1210-1-1/8 |

1-1/8″ |

D+1/8″ |

0.16 |

||||

|

1210-1-3/16 |

1-3/16″ |

D+1/8″ |

0.16 |

||||

|

1210-1-1/4 |

1-1/4″ |

D+1/8″ |

0.13 |

Cast iron: GG20

Tools for tighten: Allen wrench 3/16″

Screw Specification: 3/8-16BSW x5/8

Screws Quantity: 2

Transmissible torque: 407Nm

Screw tightening torque: 19. 6Nm

Bore In Metric

|

Product Model |

DI |

D2 |

s |

D(G7) |

b |

Js9 |

t |

Weight (Kg) |

|

1215-11MM 1215-12MM 1215-14MM 1215-15MM 1215-16MM 1215-17MM |

47.55 |

44.44 |

38.1 |

11 12 |

4 |

D+1.8 D+1.8 |

0.38 0.36 |

|

|

14 15 16 17 18 19 |

5 6 8 |

±0.015 ±0.018 |

D+2.3 D+2.3 D+2.3 D+2.3 D+2.8 D+2.8 D+2.8 D+2.8 D+3.3 D+3.3 D+3.3 D+3.3 |

0.36 0.35 0.35 0.34 0.33 0.33 0.29 0.3 0.29 0.28 0.24 0.22 |

||||

|

1215-18MM 1215-19MM 1215-20MM 1215-22MM |

||||||||

|

20 22 24 25 28 30 |

||||||||

|

1215-24MM 1215-25MM 1215-28MM 1215-30MM |

||||||||

|

1215-32MM |

32 |

10 |

D+3.3 |

0.2 |

Bore In Inches

|

Product Model |

DI |

D2 |

s |

D(G7) |

b |

t |

Weight (Kg) |

|

1215-1/2 |

1.872″ |

1.75” |

1.5″ |

1/2″ |

1/8″ |

D+1/16″ |

0.36 |

|

1215-5/8 1215-11/16 1215-3/4 |

5/8″ 11/16″ 3/4″ |

3/16″ |

D+3/32″ D+3/32″ D+3/32″ |

0.36 0.34 0.34 |

|||

|

1215-13/16 1215-7/8 1215-15/16 1215-1 |

13/16″ 7/8″ 15/16″ 1″ |

1/4″ |

D+1/8″ D+1/8″ D+1/8″ D+1/8″ |

0.34 0.33 0.33 0.29 |

|||

|

1215-1-1/16 1215-1-1/8 1215-1-3/16 1215-1-1/4 |

1-1/16″ 1-1/8″ 1-3/16″ 1-1/4″ |

5/16″ |

D+1/8″ D+1/8″ D+1/8″ D+1/8″ |

0.25 0.22 0.22 0.2 |

This taper lock bushing is a high quality as European standard, durable, and dependable product that has been precisely manufactured. The material is GG25 or steel C45. Phosphating and blackening treatment on the surface。They are used in a wide range of applications including; belt pulleys, sprockets, drum pulleys, drive pulleys, tail pulleys, sheaves, and gears, which are items that we also offer! Additionally this bushing with a flexible bore with a standard keyway suit different shaft diameter. For more information on taper lock bushings, please contact us and we will be happy to assist you.

Product detail pictures:

Related Product Guide:

Sticking to your belief of "Creating solutions of high quality and generating buddies with people from all around the world", we always put the fascination of customers to start with for Best Price for Taper Bushings Eu Standard - Taper Bushings per European Standard, in Cast GG20 or Steel C45 – GOODLUCK , The product will supply to all over the world, such as: India, Indonesia, Israel, We firmly think that we have the full capability to give you contented merchandise. Wish to collect concerns within you and build a new long-term synergy romantic relationship. We all significantly promise:Csame excellent, better selling price; exact selling price, better quality.

It is not easy to find such a professional and responsible provider in today's time. Hope that we can maintain long-term cooperation.