GS Claming Couplings, Type 1a/1a in AL/Steel

GSCOUPLINGS (CLAMPING AL,STEEL)

|

ITEM |

STOCK BORE |

dmin dmax

|

Size(mm) |

Fastening screw

|

Clamping |

|||||||||||||||

|

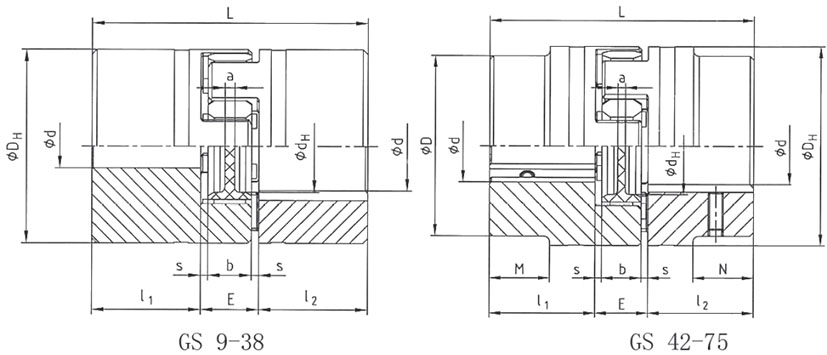

D |

DH |

dH |

L |

L1;L2 |

M/N |

E |

b |

S |

a |

|||||||||||

|

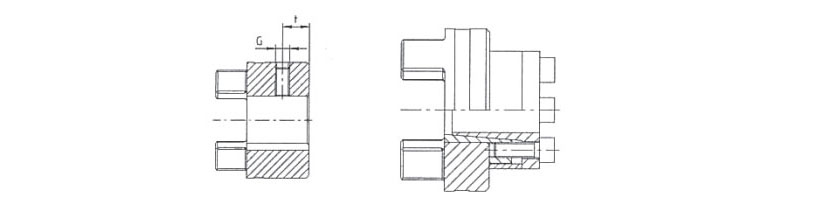

G |

t |

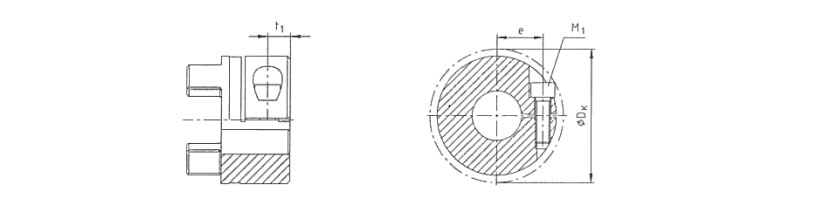

M1 |

t1 |

e |

DK |

TA (Nm) |

||||||||||||||

|

(AL-H) |

||||||||||||||||||||

|

9 |

• |

4 |

11 |

- |

20 |

7.2 |

30 |

10 |

- |

10 |

8 |

1.0 |

1.5 |

M4 |

5.0 |

M2.5 |

5.0 |

7.5 |

23.4 |

0.76 |

|

12 |

• |

4 |

12 |

- |

25 |

8.5 |

34 |

11 |

- |

12 |

10 |

1.0 |

1.5 |

M4 |

5.0 |

M3 |

5.0 |

9.0 |

27.5 |

1.34 |

|

14 |

• |

5 |

16 |

- |

30 |

10.5 |

35 |

11 |

- |

13 |

10 |

1.5 |

2.0 |

M4 |

5.0 |

M3 |

5.0 |

11.5 |

32.2 |

1.34 |

|

19” |

• |

6 |

24 |

- |

40 |

18 |

66 |

25 |

- |

16 |

12 |

2.0 |

3 |

M5 |

10 |

M6 |

12 |

14.5 |

46 |

10.5 |

|

24 |

• |

8 |

28 |

- |

55 |

27 |

78 |

30 |

- |

18 |

14 |

2.0 |

3 |

M5 |

10 |

M6 |

10.5 |

20 |

57 |

10.5 |

|

28 |

• |

10 |

38 |

- |

65 |

30 |

90 |

35 |

- |

20 |

15 |

2.5 |

4 |

M8 |

15 |

M8 |

11.5 |

25 |

73 |

25.0 |

|

38 |

• |

12 |

45 |

- |

80 |

38 |

114 |

45 |

- |

24 |

18 |

3.0 |

4 |

M8 |

15 |

M8 |

15.5 |

30 |

83 |

25.0 |

|

(St-H) |

||||||||||||||||||||

|

42 |

• |

14 |

55 |

85 |

95 |

46 |

126 |

50 |

28 |

26 |

20 |

3.0 |

4.0 |

M8 |

20 |

M10 |

18 |

32 |

94 |

69 |

|

48 |

• |

15 |

62 |

95 |

105 |

51 |

140 |

56 |

32 |

28 |

21 |

3.5 |

4.0 |

M8 |

20 |

M12 |

21 |

36 |

105 |

120 |

|

55 |

• |

20 |

74 |

110 |

120 |

60 |

160 |

65 |

37 |

30 |

22 |

4.0 |

4.5 |

M10 |

20 |

M12 |

26 |

42.5 |

120 |

120 |

|

65 |

• |

22 |

80 |

115 |

135 |

68 |

185 |

75 |

47 |

35 |

26 |

4.5 |

4.5 |

M10 |

20 |

M12 |

33 |

45 |

124 |

120 |

|

75 |

• |

30 |

95 |

135 |

160 |

80 |

210 |

85 |

53 |

40 |

30 |

5 |

5 |

M10 |

25 |

M16 |

36 |

51 |

147.5 |

295 |

|

GS |

2.0/2.5(Nm ) |

|||||||||||||||||||||||||||

|

Model |

ø8 |

ø10 |

ø11 |

ø14 |

ø15 |

ø16 |

ø18 |

ø19 |

ø20 |

ø22 |

ø24 |

ø25 |

ø28 |

ø30 |

ø32 |

ø35 |

ø38 |

ø40 |

ø42 |

ø45 |

ø48 |

ø50 |

ø55 |

ø60 |

ø65 |

ø70 |

ø75 |

ø80 |

|

19 |

25 |

27 |

27 |

29 |

30 |

31 |

32 |

32 |

34 |

302) |

322, |

|||||||||||||||||

|

24 |

34 |

35 |

36 |

38 |

38 |

39 |

40 |

41 |

42 |

43 |

45 |

46 |

||||||||||||||||

|

28 |

80 |

81 |

81 |

84 |

85 |

87 |

89 |

91 |

92 |

97 |

99 |

102 |

105 |

109 |

||||||||||||||

|

38 |

92 |

94 |

97 |

98 |

99 |

102 |

104 |

105 |

109 |

112 |

113 |

118 |

122 |

123 |

126 |

130 |

||||||||||||

|

42 |

232 |

238 |

244 |

246 |

255 |

260 |

266 |

274 |

283 |

288 |

294 |

301 |

309 |

|||||||||||||||

|

48 |

393 |

405 |

413 |

421 |

434 |

445 |

454 |

462 |

473 |

486 |

494 |

514 |

||||||||||||||||

|

55 |

473 |

486 |

498 |

507 |

514 |

526 |

539 |

547 |

567 |

587 |

608 |

|||||||||||||||||

|

65 |

507 |

518 |

526 |

535 |

547 |

559 |

567 |

587 |

608 |

627 |

648 |

|||||||||||||||||

|

75 |

1102 |

1124 |

1148 |

1163 |

1201 |

1239 |

1278 |

1316 |

1354 |

1393 |

||||||||||||||||||

GS couplings are deigned to transmit torque between drive and driven components via curved jaw hubs and elastomeric elements commonly known as spiders. The combination between these components provides dampening and accommodation for misalignments. This product is available in a variety of metals, elastomers and mounting configurations to meet your specific needs. Ordering Guide: There are three individual part numbers you will need for a complete coupling (i.e., 2 Hubs and 1 Spider). Please choose the hub sizes that match the criteria for your application.