Leading Manufacturer for Odham Couplings - GE Couplings, Type 1/1, 1a/1a, 1b/1b in AL/Cast/Steel – GOODLUCK

Leading Manufacturer for Odham Couplings - GE Couplings, Type 1/1, 1a/1a, 1b/1b in AL/Cast/Steel – GOODLUCK Detail:

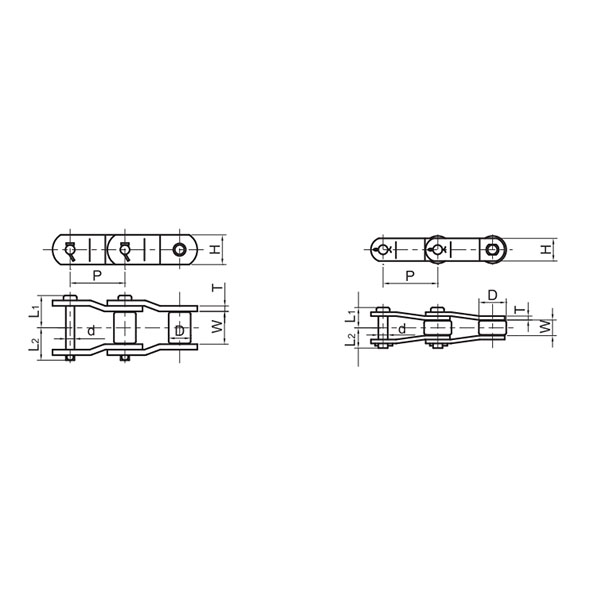

GE COUPLINGS (AL, CAST)

|

GE(AL-H) |

|||||||||||||||||

|

ITEM |

PART |

(Nm) |

size(mm) |

||||||||||||||

|

d(min-max) |

Overall dimensions |

Set screw |

|||||||||||||||

|

92 Sh A |

98 Sh A |

64 Sh D |

L |

l1;l2 |

E |

b |

s |

DH |

dH |

D ; D1 |

N |

G |

t |

TA(Nm) |

|||

|

14 |

1a |

7.5 |

12.5 |

- |

6-16 |

35 |

11 |

13 |

10 |

1.5 |

30 |

10 |

30 |

- |

M4 |

5 |

1.5 |

|

19 |

1 |

10 |

17 |

- |

6-19 |

66 |

25 |

16 |

12 |

2 |

40 |

18 |

32 |

20 |

M5 |

10 |

2 |

|

1a |

19-24 |

40 |

|||||||||||||||

|

24 |

1 |

35 |

60 |

- |

9-24 |

78 |

30 |

18 |

14 |

2 |

55 |

27 |

40 |

24 |

M5 |

10 |

2 |

|

1a |

22-28 |

55 |

|||||||||||||||

|

28 |

1 |

95 |

160 |

- |

10-28 |

90 |

35 |

20 |

15 |

2.5 |

65 |

30 |

48 |

28 |

M8 |

15 |

10 |

|

1a |

28-38 |

65 |

|||||||||||||||

GE EN-GJL-250 ( GG 25 )

|

1 |

12-38 |

66 |

|||||||||||||||

|

38 |

1a |

190 |

325 |

405 |

38-45 |

114 |

45 |

24 |

18 |

3 |

80 |

38 |

37 |

M8 |

15 |

10 |

|

|

1b |

12-45 |

164 |

70 |

62 |

|||||||||||||

|

1 |

14-42 |

75 |

|||||||||||||||

|

42 |

1a |

265 |

450 |

560 |

42-55 |

126 |

50 |

26 |

20 |

3 |

95 |

46 |

94 |

40 |

M8 |

20 |

10 |

|

1b |

14-55 |

176 |

75 |

65 |

|||||||||||||

|

1 |

15-48 |

85 |

|||||||||||||||

|

48 |

1a |

310 |

525 |

655 |

48-60 |

140 |

56 |

28 |

21 |

3.5 |

105 |

51 |

45 |

M8 |

20 |

10 |

|

|

1b |

15-60 |

188 |

80 |

69 |

|||||||||||||

|

1 |

20-55 |

98 |

|||||||||||||||

|

55 |

1a |

410 |

685 |

825 |

55-70 |

160 |

65 |

30 |

22 |

4 |

120 |

60 |

118 |

M10 |

20 |

17 |

|

|

1b |

20-70 |

210 |

90 |

120 |

- |

||||||||||||

|

1 |

22-65 |

115 |

61 |

||||||||||||||

|

65 |

1a |

625 |

940 |

1175 |

65-80 |

185 |

75 |

35 |

26 |

4.5 |

135 |

68 |

M10 |

20 |

17 |

||

|

1b |

22-80 |

235 |

100 |

||||||||||||||

|

1 |

30-75 |

135 |

69 |

||||||||||||||

|

75 |

1a |

1280 |

1920 |

2400 |

75-95 |

210 |

85 |

40 |

30 |

5 |

160 |

80 |

1RQ |

M10 |

25 |

17 |

|

|

1b |

30-95 |

260 |

110 |

||||||||||||||

|

1 |

40-90 |

160 |

81 |

||||||||||||||

|

90 |

1a |

2400 |

3600 |

4500 |

90-110 |

245 |

100 |

45 |

34 |

5.5 |

200 |

100 |

M12 |

30 |

40 |

||

|

1b |

40-110 |

295 |

125 |

GE EN-GJL-400-15 ( GGg 40 )

|

100 |

1 |

3300 |

4950 |

6185 |

50-115 |

270 |

110 |

50 |

38 |

6 |

225 |

113 |

180 |

89 |

M12 |

30 |

40 |

|

110 |

1 |

4800 |

7200 |

9000 |

60-125 |

295 |

120 |

55 |

42 |

6.5 |

255 |

127 |

200 |

96 |

M16 |

35 |

80 |

|

125 |

1 |

6650 |

10000 |

12500 |

60-145 |

340 |

140 |

60 |

46 |

7 |

290 |

147 |

230 |

112 |

M16 |

40 |

80 |

|

140 |

1 |

8550 |

12800 |

16000 |

60-160 |

375 |

155 |

65 |

50 |

7.5 |

320 |

165 |

255 |

124 |

M20 |

45 |

140 |

|

160 |

1 |

12800 |

19200 |

24000 |

80-185 |

425 |

175 |

75 |

57 |

9 |

370 |

190 |

290 |

140 |

M20 |

50 |

140 |

|

180 |

1 |

18650 |

28000 |

35000 |

85-200 |

475 |

185 |

85 |

64 |

10.5 |

420 |

220 |

325 |

156 |

M20 |

50 |

140 |

|

GE (STEEL) |

|||||||||||||||||

|

ITEM |

PART |

(Nm) |

SIZE (mm) |

||||||||||||||

|

d(min-max) |

Overall dimensions |

Special dimensions of steel sleeve |

Set screw |

||||||||||||||

|

92 Sh A |

98 Sh A |

64 Sh D |

L |

E |

b |

s |

DH |

dh |

D;D1 |

N |

G |

t |

TA(Nm) |

||||

|

14 |

1a |

7.5 |

12.5 |

16 |

0-16 |

35 |

11 |

13 |

10 |

1.5 |

30 |

10 |

30 |

- |

M4 |

5 |

1.5 |

|

1b |

50 |

18.5 |

|||||||||||||||

|

19 |

1a |

10 |

17 |

21 |

0-25 |

66 |

25 |

16 |

12 |

2 |

40 |

18 |

40 |

M5 |

10 |

2 |

|

|

1b |

90 |

37 |

|||||||||||||||

|

24 |

1a |

35 |

60 |

75 |

0-35 |

78 |

30 |

18 |

14 |

2 |

55 |

27 |

55 |

M5 |

10 |

2 |

|

|

1b |

118 |

50 |

|||||||||||||||

|

28 |

1a |

95 |

160 |

200 |

0-40 |

90 |

35 |

20 |

15 |

2.5 |

65 |

30 |

65 |

- |

M8 |

15 |

10 |

|

1b |

140 |

60 |

|||||||||||||||

|

38 |

1 |

190 |

325 |

405 |

0-48 |

114 |

45 |

24 |

18 |

3 |

80 |

38 |

70 |

27 |

M8 |

15 |

10 |

|

1b |

164 |

70 |

85 |

- |

|||||||||||||

|

42 |

1 |

265 |

450 |

560 |

0-55 |

126 |

50 |

26 |

20 |

3 |

95 |

46 |

85 |

28 |

M8 |

20 |

10 |

|

1b |

176 |

75 |

95 |

- |

|||||||||||||

|

48 |

1 |

310 |

525 |

655 |

0-62 |

140 |

56 |

28 |

21 |

3.5 |

105 |

51 |

95 |

32 |

M8 |

20 |

10 |

|

1b |

188 |

80 |

105 |

- |

|||||||||||||

|

55 |

1 |

410 |

685 |

825 |

0-74 |

160 |

65 |

30 |

22 |

4 |

120 |

60 |

110 |

37 |

M10 |

20 |

17 |

|

1b |

210 |

90 |

120 |

- |

|||||||||||||

|

65 |

1 |

625 |

940 |

1175 |

0-80 |

185 |

75 |

35 |

26 |

4.5 |

135 |

68 |

115 |

47 |

M10 |

20 |

17 |

|

1b |

235 |

100 |

135 |

- |

|||||||||||||

|

75 |

1 |

1280 |

1920 |

2400 |

0-95 |

210 |

85 |

40 |

30 |

5 |

160 |

80 |

135 |

53 |

M10 |

25 |

17 |

|

1b |

260 |

110 |

160 |

- |

|||||||||||||

|

90 |

1 |

2400 |

3600 |

4500 |

0-110 |

245 |

100 |

45 |

34 |

5.5 |

200 |

100 |

160 |

62 |

M12 |

30 |

40 |

|

1b |

295 |

125 |

200 |

- |

|||||||||||||

GE(GG25)

|

ITEM |

TB |

size(mm) |

Mounting screw of shaft sleeve |

|||||||||||

|

l1;l2 |

E |

S |

b |

L |

N |

DH |

D1 |

dH |

Specification |

length |

number |

TA (Nm) |

||

|

24 |

1008 |

23 |

18 |

2.0 |

14 |

64 |

一 |

55 |

55 |

27 |

1/4 |

13 |

2 |

5.7 |

|

28 |

1108 |

23 |

20 |

2.5 |

15 |

66 |

一 |

65 |

65 |

30 |

1/4” |

13 |

2 |

5.7 |

|

38 |

1108 |

23 |

24 |

3.0 |

18 |

70 |

15 |

80 |

78 |

38 |

1/4” |

13 |

2 |

5.7 |

|

42 |

1610 |

26 |

26 |

3.0 |

20 |

78 |

16 |

95 |

94 |

46 |

3/8” |

16 |

2 |

20 |

|

48 |

1615 |

39 |

28 |

3.5 |

21 |

106 |

28 |

105 |

104 |

51 |

3/8“ |

16 |

2 |

20 |

|

55 |

2012 |

33 |

30 |

4.0 |

22 |

96 |

20 |

120 |

118 |

60 |

7/16” |

22 |

2 |

31 |

|

65 |

2012 |

33 |

35 |

4.5 |

26 |

101 |

19 |

135 |

115 |

68 |

7/16” |

22 |

2 |

31 |

|

2517 |

1/2” |

25 |

49 |

|||||||||||

|

75 |

. 3020 |

52 |

40 |

5.0 |

30 |

144 |

36 |

160 |

158 |

80 |

5/8″ |

32 |

2 |

92 |

|

90 |

3020 |

52 |

45 |

5.5 |

24 |

144 |

33 |

200 |

160 |

100 |

5/8“ |

32 |

2 |

92 |

|

125 |

3535 |

90 |

60 |

147 |

1/2” |

3 |

113 |

|||||||

|

4545 |

114 |

3/4″ |

49 |

192 |

||||||||||

*ONLY FOR H TYPE *BSW SCREW

|

Cone sleeve |

|||||||||||||||||||

|

Specification |

The tolerance of finished hole diameter D1 can be H7 keyway according to DIN 6885 / 1 |

||||||||||||||||||

|

1008 |

10 |

11 |

12 |

14 |

16 |

18 |

19 |

20 |

22 |

24 |

25 |

||||||||

|

1108 |

10 |

11 |

12 |

14 |

16 |

18 |

19 |

20 |

22 |

24 |

25 |

28* |

|||||||

|

1610 |

14 |

16 |

18 |

19 |

20 |

22 |

24 |

25 |

28 |

30 |

32 |

35 |

38 |

40 |

42* |

||||

|

1615 |

14 |

16 |

18 |

19 |

20 |

22 |

24 |

25 |

28 |

30 |

32 |

35 |

38 |

40 |

42* |

||||

|

2012 |

14 |

16 |

18 |

19 |

20 |

22 |

24 |

25 |

28 |

30 |

32 |

35 |

38 |

40 |

42 |

45 |

48 |

50 |

|

|

2517 |

16 |

18 |

19 |

20 |

22 |

24 |

25 |

28 |

30 |

32 |

35 |

38 |

40 |

42 |

45 |

48 |

50 |

55 |

60 |

|

3020 |

25 |

28 |

30 |

35 |

38 |

40 |

42 |

45 |

48 |

50 |

55 |

60 |

65 |

70 |

75 |

||||

|

3535 |

35 |

38 |

40 |

42 |

45 |

48 |

50 |

55 |

60 |

65 |

70 |

75 |

80 |

85 |

90 |

||||

|

4545 |

55 |

60 |

65 |

70 |

75 |

80 |

85 |

90 |

95 |

100 |

105 |

110 |

|||||||

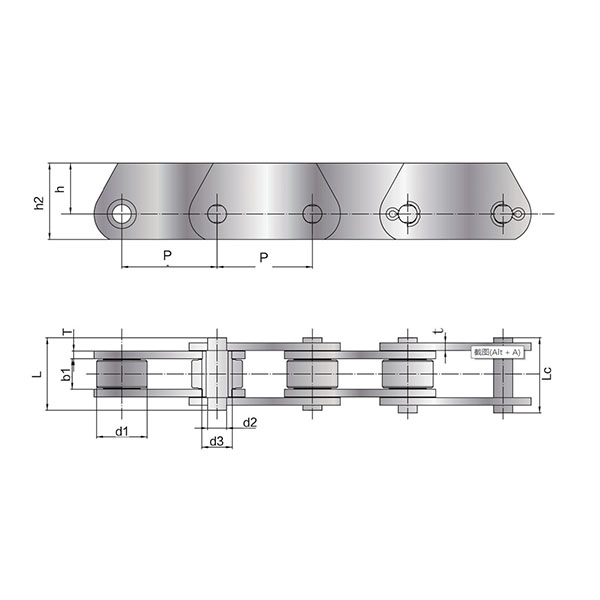

GL GE couplings are designed to transmit torque between drive and driven components with zero‑backlash via curved jaw hubs and elastomeric elements, commonly known as spiders. The combination of these components provides dampening and accommodation of misalignment. This product is available in a variety of metals, elastomers and mounting configurations to meet your specific needs. GL GS couplings suitable for horizontal or vertical applications are constructed from a variety of materials, providing a torsionally flexible zero‑backlash platform optimizing the balance between inertia, coupling performance and application requirements. The machined concaved jaws provide a pocket to preload the spider legs, allowing the spiders to articulate freely while accommodating misalignment, minimizing restoring forces, dampen shock and vibration, while providing failsafe zero‑backlash torque transmission. The symmetrical relationship of the hubs allows for a variety of accessories to accommodate different shaft distances.

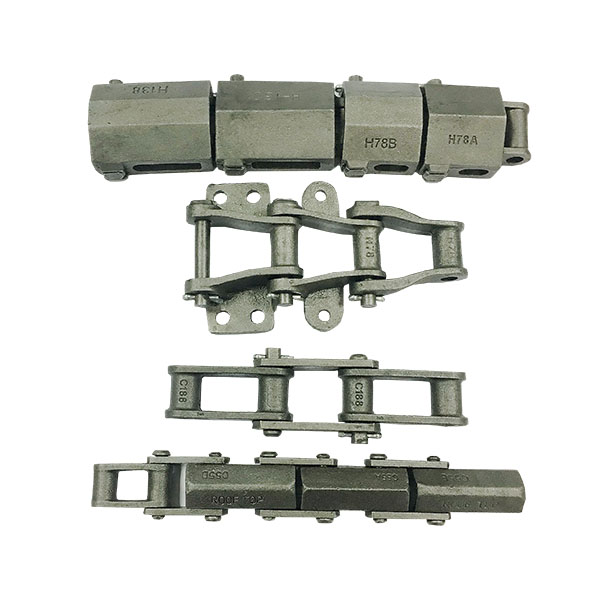

Product detail pictures:

Related Product Guide:

Our solutions are widely regarded and trustworthy by consumers and may meet continually modifying financial and social requirements for Leading Manufacturer for Odham Couplings - GE Couplings, Type 1/1, 1a/1a, 1b/1b in AL/Cast/Steel – GOODLUCK , The product will supply to all over the world, such as: Bahamas, Argentina, Egypt, Our business activities and processes are engineered to make sure our customers have access to widest range of products with the shortest supply time lines. This achievement is made possible by our highly skilled and experienced team. We look for people who want to grow with us around the globe and stand out from the crowd. We now have people who embrace tomorrow, have vision, love stretching their minds and going far beyond what they thought was achievable.

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!