Low MOQ for Surflex Couplings - Weld-On-Hubs, Type W, WH,WM per C20 Material – GOODLUCK

Low MOQ for Surflex Couplings - Weld-On-Hubs, Type W, WH,WM per C20 Material – GOODLUCK Detail:

Weld-on-Hubs

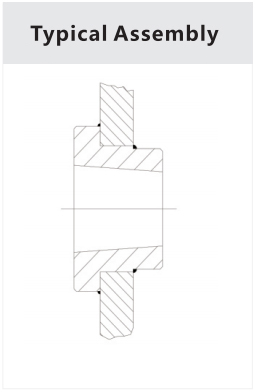

Taper Bore Weld-on-Hubs are made out of steel,drilled, tapped and taper bored to receive standard Taper Bushes. The extended flange provides a convenient means of welding hubs into fan rotors, steel pulleys, plate sprockets, impellers, agitators and many other devices which must be firmly fastened the shaft. Weld-on-Hubs are easy to install and entirely suitable for use where severe operating conditions are met. Tightening the xcrews contracts the bore of the bush, thereby looking it to the shaft with the equivalent of press fit .This type of construction eliminates mounting difficulties, it also prevents loosening and wear on the hub during operation. Weld-on-Hubs are manufactured to complemen Taper Bush range and include W,WG,WH, WHG, WM and WMG Taper Bore Hubs. All are manufactured to world standards using C20 steel.

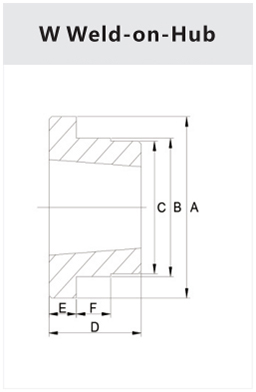

W Weld-on-Hubs

|

Hub |

Bush Size |

A |

B |

C |

D |

E |

F |

Fl |

X |

|

W12 |

1215 |

73.03 |

63.50 |

62.71 |

38.10 |

15.88 |

9.53 |

- |

- |

|

W16 |

1615 |

82.55 |

73.03 |

72.24 |

38.10 |

15388 |

9.53 |

- |

- |

|

W25 |

2517 |

127.00 |

111.13 |

110.34 |

44.45 |

19.05 |

12.70 |

- |

- |

|

WG30 |

3030 |

149.86 |

133.35 |

132.56 |

76.20 |

25.40 |

19.05 |

23 |

23 |

|

WG35 |

3535 |

184.15 |

158.75 |

157.96 |

88.90 |

31.75 |

25.04 |

30 |

30 |

|

WG40 |

4040 |

225.43 |

169.85 |

196.06 |

101.60 |

31.75 |

31.75 |

34 |

34 |

|

WG45 |

4545 |

254.00 |

222.25 |

221.46 |

114.30 |

38.10 |

38.10 |

38 |

38 |

|

WG50 |

5050 |

267.00 |

241.00 |

240.25 |

127.00 |

38.10 |

38.10 |

42 |

42 |

|

WG60 |

6060 |

375.00 |

343.00 |

342.00 |

127.00 |

38.10 |

38.10 |

42 |

42 |

|

WG70 |

7060 |

425.00 |

375.00 |

374.00 |

153.00 |

51.00 |

51.00 |

51 |

51 |

|

WG80 |

8065 |

445.00 |

349.0 |

393.00 |

165.00 |

51.00 |

51.00 |

55 |

55 |

|

WG100 |

10085 |

559.00 |

495.00 |

494.00 |

216.00 |

51.00 |

51.00 |

72 |

72 |

“G”: natation represents welding relief

Weld-on-Hubs

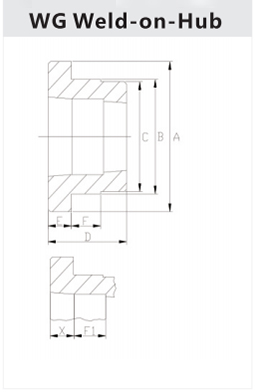

WH Weld-on-Hubs

|

Hub Reference |

Bush Size |

A |

B |

C |

D |

E |

F |

Fl X |

|

|

WH12 |

1210 |

70 |

65 |

64.5 |

25 |

9 |

10 |

- |

- |

|

WH16-1 |

1610 |

80 |

75 |

74.5 |

25 |

9 |

10 |

- |

- |

|

WH20 |

2012 |

95 |

90 |

89.5 |

32 |

12 |

12 |

- |

- |

|

WH25 |

2517 |

115 |

110 |

109.5 |

44 |

19 |

15 |

- |

- |

|

WHG30-2 |

3020 |

145 |

140 |

139.5 |

50 |

20 |

15 |

17 |

17 |

|

WHG35 |

3525 |

190 |

180 |

179.5 |

65 |

25 |

25 |

22 |

22 |

|

WHG40-1 |

4030 |

200 |

190 |

189.0 |

76 |

32 |

30 |

25 |

25 |

|

WHG40-2 |

4040 |

200 |

190 |

189.0 |

101 |

32 |

30 |

34 |

34 |

|

WHG45-1 |

4535 |

210 |

200 |

199.5 |

89 |

40 |

30 |

30 |

30 |

|

WHG45-2 |

4545 |

210 |

200 |

199.5 |

114 |

40 |

30 |

38 |

38 |

|

WHG50-1 |

5040 |

230 |

220 |

219.5 |

102 |

40 |

35 |

34 |

34 |

|

WHG50-2 |

5050 |

230 |

220 |

219.5 |

127 |

40 |

35 |

42 |

42 |

“GH”: natation represents welding relief

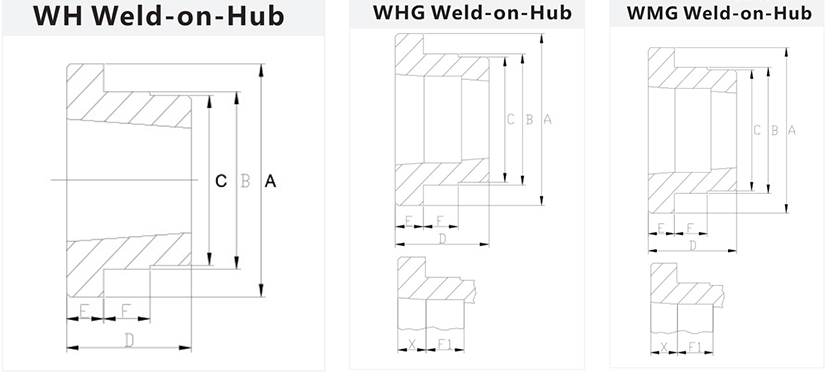

WMG Weld-on-Hub

|

Hub Reference |

Bush Size |

A |

B |

C |

D |

E |

F |

Fl |

X |

|

WMG12 |

1210 |

70 |

60 |

58 |

26 |

9 |

10 |

9 |

9 |

|

WMG16-1 |

1610 |

83 |

70 |

68 |

26 |

9 |

10 |

9 |

9 |

|

WMG16-1 |

1615 |

83 |

70 |

68 |

38 |

16 |

11 |

13 |

13 |

|

WMG20 |

2012 |

95 |

90 |

88 |

32 |

12 |

12 |

11 |

11 |

|

WMG25 |

2517 |

127 |

110 |

108 |

44 |

19 |

13 |

15 |

15 |

|

WMG30-2 |

3020 |

150 |

130 |

125 |

50 |

20 |

15 |

17 |

17 |

|

WMG30-3 |

3030 |

150 |

130 |

125 |

76 |

25 |

19 |

25 |

25 |

|

WMG35 |

3535 |

184 |

155 |

151 |

89 |

32 |

25 |

30 |

30 |

|

WMG40 |

4040 |

225 |

195 |

187 |

102 |

32 |

32 |

34 |

34 |

|

WMG45 |

4545 |

254 |

220 |

213 |

114 |

38 |

38 |

38 |

38 |

|

WMG50 |

5050 |

276 |

242 |

228 |

127 |

38 |

38 |

42 |

42 |

Weld-on-hubs are made of C20 steel and drilled, tapped and coned to accommodate tapered lock bushings. They can be used for welding into pulleys, sprockets, couplings, fan rotors, belt wheels, etc. These components must be securely mounted on shafting. Four types of weld-on-hubs are available off the shelf.Type:W, WG, WH, WHG, WM, WMG taper bore hubs.

Product detail pictures:

Related Product Guide:

The customer satisfaction is our primary target. We uphold a consistent level of professionalism, quality, credibility and service for Low MOQ for Surflex Couplings - Weld-On-Hubs, Type W, WH,WM per C20 Material – GOODLUCK , The product will supply to all over the world, such as: Adelaide, Lesotho, Sierra Leone, Our items have national accreditation requirements for qualified, high quality goods, affordable value, was welcomed by people today all over the world. Our products will continue to enhance within the order and look forward to cooperation with you, Should really any of these products and solutions be of curiosity to you, be sure to letus know. We are likely to be content to offer you a quotation up on receipt of your detailed needs.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!