Manufacturer for Coupling Pin - GE Couplings, Type 1/1, 1a/1a, 1b/1b in AL/Cast/Steel – GOODLUCK

Manufacturer for Coupling Pin - GE Couplings, Type 1/1, 1a/1a, 1b/1b in AL/Cast/Steel – GOODLUCK Detail:

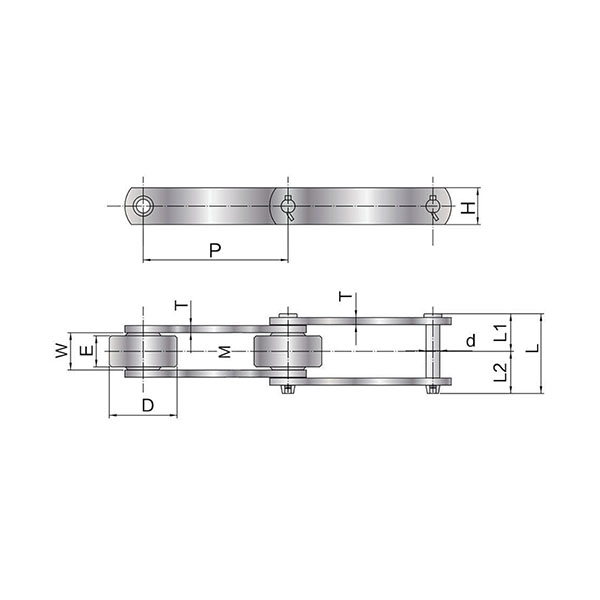

GE COUPLINGS (AL, CAST)

|

GE(AL-H) |

|||||||||||||||||

|

ITEM |

PART |

(Nm) |

size(mm) |

||||||||||||||

|

d(min-max) |

Overall dimensions |

Set screw |

|||||||||||||||

|

92 Sh A |

98 Sh A |

64 Sh D |

L |

l1;l2 |

E |

b |

s |

DH |

dH |

D ; D1 |

N |

G |

t |

TA(Nm) |

|||

|

14 |

1a |

7.5 |

12.5 |

- |

6-16 |

35 |

11 |

13 |

10 |

1.5 |

30 |

10 |

30 |

- |

M4 |

5 |

1.5 |

|

19 |

1 |

10 |

17 |

- |

6-19 |

66 |

25 |

16 |

12 |

2 |

40 |

18 |

32 |

20 |

M5 |

10 |

2 |

|

1a |

19-24 |

40 |

|||||||||||||||

|

24 |

1 |

35 |

60 |

- |

9-24 |

78 |

30 |

18 |

14 |

2 |

55 |

27 |

40 |

24 |

M5 |

10 |

2 |

|

1a |

22-28 |

55 |

|||||||||||||||

|

28 |

1 |

95 |

160 |

- |

10-28 |

90 |

35 |

20 |

15 |

2.5 |

65 |

30 |

48 |

28 |

M8 |

15 |

10 |

|

1a |

28-38 |

65 |

|||||||||||||||

GE EN-GJL-250 ( GG 25 )

|

1 |

12-38 |

66 |

|||||||||||||||

|

38 |

1a |

190 |

325 |

405 |

38-45 |

114 |

45 |

24 |

18 |

3 |

80 |

38 |

37 |

M8 |

15 |

10 |

|

|

1b |

12-45 |

164 |

70 |

62 |

|||||||||||||

|

1 |

14-42 |

75 |

|||||||||||||||

|

42 |

1a |

265 |

450 |

560 |

42-55 |

126 |

50 |

26 |

20 |

3 |

95 |

46 |

94 |

40 |

M8 |

20 |

10 |

|

1b |

14-55 |

176 |

75 |

65 |

|||||||||||||

|

1 |

15-48 |

85 |

|||||||||||||||

|

48 |

1a |

310 |

525 |

655 |

48-60 |

140 |

56 |

28 |

21 |

3.5 |

105 |

51 |

45 |

M8 |

20 |

10 |

|

|

1b |

15-60 |

188 |

80 |

69 |

|||||||||||||

|

1 |

20-55 |

98 |

|||||||||||||||

|

55 |

1a |

410 |

685 |

825 |

55-70 |

160 |

65 |

30 |

22 |

4 |

120 |

60 |

118 |

M10 |

20 |

17 |

|

|

1b |

20-70 |

210 |

90 |

120 |

- |

||||||||||||

|

1 |

22-65 |

115 |

61 |

||||||||||||||

|

65 |

1a |

625 |

940 |

1175 |

65-80 |

185 |

75 |

35 |

26 |

4.5 |

135 |

68 |

M10 |

20 |

17 |

||

|

1b |

22-80 |

235 |

100 |

||||||||||||||

|

1 |

30-75 |

135 |

69 |

||||||||||||||

|

75 |

1a |

1280 |

1920 |

2400 |

75-95 |

210 |

85 |

40 |

30 |

5 |

160 |

80 |

1RQ |

M10 |

25 |

17 |

|

|

1b |

30-95 |

260 |

110 |

||||||||||||||

|

1 |

40-90 |

160 |

81 |

||||||||||||||

|

90 |

1a |

2400 |

3600 |

4500 |

90-110 |

245 |

100 |

45 |

34 |

5.5 |

200 |

100 |

M12 |

30 |

40 |

||

|

1b |

40-110 |

295 |

125 |

GE EN-GJL-400-15 ( GGg 40 )

|

100 |

1 |

3300 |

4950 |

6185 |

50-115 |

270 |

110 |

50 |

38 |

6 |

225 |

113 |

180 |

89 |

M12 |

30 |

40 |

|

110 |

1 |

4800 |

7200 |

9000 |

60-125 |

295 |

120 |

55 |

42 |

6.5 |

255 |

127 |

200 |

96 |

M16 |

35 |

80 |

|

125 |

1 |

6650 |

10000 |

12500 |

60-145 |

340 |

140 |

60 |

46 |

7 |

290 |

147 |

230 |

112 |

M16 |

40 |

80 |

|

140 |

1 |

8550 |

12800 |

16000 |

60-160 |

375 |

155 |

65 |

50 |

7.5 |

320 |

165 |

255 |

124 |

M20 |

45 |

140 |

|

160 |

1 |

12800 |

19200 |

24000 |

80-185 |

425 |

175 |

75 |

57 |

9 |

370 |

190 |

290 |

140 |

M20 |

50 |

140 |

|

180 |

1 |

18650 |

28000 |

35000 |

85-200 |

475 |

185 |

85 |

64 |

10.5 |

420 |

220 |

325 |

156 |

M20 |

50 |

140 |

|

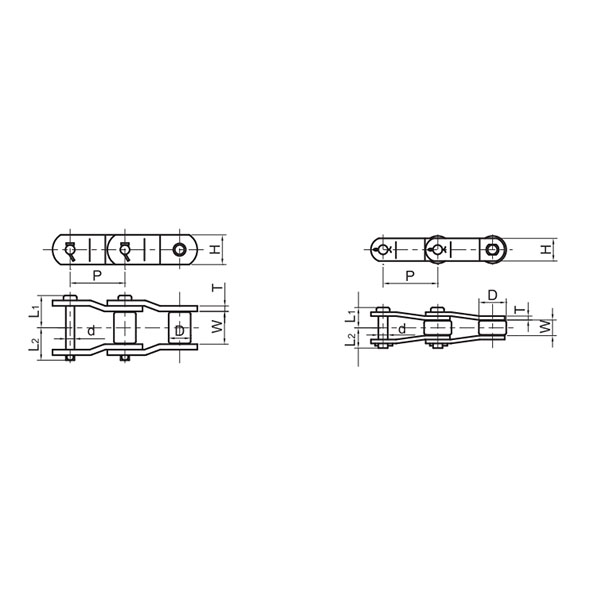

GE (STEEL) |

|||||||||||||||||

|

ITEM |

PART |

(Nm) |

SIZE (mm) |

||||||||||||||

|

d(min-max) |

Overall dimensions |

Special dimensions of steel sleeve |

Set screw |

||||||||||||||

|

92 Sh A |

98 Sh A |

64 Sh D |

L |

E |

b |

s |

DH |

dh |

D;D1 |

N |

G |

t |

TA(Nm) |

||||

|

14 |

1a |

7.5 |

12.5 |

16 |

0-16 |

35 |

11 |

13 |

10 |

1.5 |

30 |

10 |

30 |

- |

M4 |

5 |

1.5 |

|

1b |

50 |

18.5 |

|||||||||||||||

|

19 |

1a |

10 |

17 |

21 |

0-25 |

66 |

25 |

16 |

12 |

2 |

40 |

18 |

40 |

M5 |

10 |

2 |

|

|

1b |

90 |

37 |

|||||||||||||||

|

24 |

1a |

35 |

60 |

75 |

0-35 |

78 |

30 |

18 |

14 |

2 |

55 |

27 |

55 |

M5 |

10 |

2 |

|

|

1b |

118 |

50 |

|||||||||||||||

|

28 |

1a |

95 |

160 |

200 |

0-40 |

90 |

35 |

20 |

15 |

2.5 |

65 |

30 |

65 |

- |

M8 |

15 |

10 |

|

1b |

140 |

60 |

|||||||||||||||

|

38 |

1 |

190 |

325 |

405 |

0-48 |

114 |

45 |

24 |

18 |

3 |

80 |

38 |

70 |

27 |

M8 |

15 |

10 |

|

1b |

164 |

70 |

85 |

- |

|||||||||||||

|

42 |

1 |

265 |

450 |

560 |

0-55 |

126 |

50 |

26 |

20 |

3 |

95 |

46 |

85 |

28 |

M8 |

20 |

10 |

|

1b |

176 |

75 |

95 |

- |

|||||||||||||

|

48 |

1 |

310 |

525 |

655 |

0-62 |

140 |

56 |

28 |

21 |

3.5 |

105 |

51 |

95 |

32 |

M8 |

20 |

10 |

|

1b |

188 |

80 |

105 |

- |

|||||||||||||

|

55 |

1 |

410 |

685 |

825 |

0-74 |

160 |

65 |

30 |

22 |

4 |

120 |

60 |

110 |

37 |

M10 |

20 |

17 |

|

1b |

210 |

90 |

120 |

- |

|||||||||||||

|

65 |

1 |

625 |

940 |

1175 |

0-80 |

185 |

75 |

35 |

26 |

4.5 |

135 |

68 |

115 |

47 |

M10 |

20 |

17 |

|

1b |

235 |

100 |

135 |

- |

|||||||||||||

|

75 |

1 |

1280 |

1920 |

2400 |

0-95 |

210 |

85 |

40 |

30 |

5 |

160 |

80 |

135 |

53 |

M10 |

25 |

17 |

|

1b |

260 |

110 |

160 |

- |

|||||||||||||

|

90 |

1 |

2400 |

3600 |

4500 |

0-110 |

245 |

100 |

45 |

34 |

5.5 |

200 |

100 |

160 |

62 |

M12 |

30 |

40 |

|

1b |

295 |

125 |

200 |

- |

|||||||||||||

GE(GG25)

|

ITEM |

TB |

size(mm) |

Mounting screw of shaft sleeve |

|||||||||||

|

l1;l2 |

E |

S |

b |

L |

N |

DH |

D1 |

dH |

Specification |

length |

number |

TA (Nm) |

||

|

24 |

1008 |

23 |

18 |

2.0 |

14 |

64 |

一 |

55 |

55 |

27 |

1/4 |

13 |

2 |

5.7 |

|

28 |

1108 |

23 |

20 |

2.5 |

15 |

66 |

一 |

65 |

65 |

30 |

1/4” |

13 |

2 |

5.7 |

|

38 |

1108 |

23 |

24 |

3.0 |

18 |

70 |

15 |

80 |

78 |

38 |

1/4” |

13 |

2 |

5.7 |

|

42 |

1610 |

26 |

26 |

3.0 |

20 |

78 |

16 |

95 |

94 |

46 |

3/8” |

16 |

2 |

20 |

|

48 |

1615 |

39 |

28 |

3.5 |

21 |

106 |

28 |

105 |

104 |

51 |

3/8“ |

16 |

2 |

20 |

|

55 |

2012 |

33 |

30 |

4.0 |

22 |

96 |

20 |

120 |

118 |

60 |

7/16” |

22 |

2 |

31 |

|

65 |

2012 |

33 |

35 |

4.5 |

26 |

101 |

19 |

135 |

115 |

68 |

7/16” |

22 |

2 |

31 |

|

2517 |

1/2” |

25 |

49 |

|||||||||||

|

75 |

. 3020 |

52 |

40 |

5.0 |

30 |

144 |

36 |

160 |

158 |

80 |

5/8″ |

32 |

2 |

92 |

|

90 |

3020 |

52 |

45 |

5.5 |

24 |

144 |

33 |

200 |

160 |

100 |

5/8“ |

32 |

2 |

92 |

|

125 |

3535 |

90 |

60 |

147 |

1/2” |

3 |

113 |

|||||||

|

4545 |

114 |

3/4″ |

49 |

192 |

||||||||||

*ONLY FOR H TYPE *BSW SCREW

|

Cone sleeve |

|||||||||||||||||||

|

Specification |

The tolerance of finished hole diameter D1 can be H7 keyway according to DIN 6885 / 1 |

||||||||||||||||||

|

1008 |

10 |

11 |

12 |

14 |

16 |

18 |

19 |

20 |

22 |

24 |

25 |

||||||||

|

1108 |

10 |

11 |

12 |

14 |

16 |

18 |

19 |

20 |

22 |

24 |

25 |

28* |

|||||||

|

1610 |

14 |

16 |

18 |

19 |

20 |

22 |

24 |

25 |

28 |

30 |

32 |

35 |

38 |

40 |

42* |

||||

|

1615 |

14 |

16 |

18 |

19 |

20 |

22 |

24 |

25 |

28 |

30 |

32 |

35 |

38 |

40 |

42* |

||||

|

2012 |

14 |

16 |

18 |

19 |

20 |

22 |

24 |

25 |

28 |

30 |

32 |

35 |

38 |

40 |

42 |

45 |

48 |

50 |

|

|

2517 |

16 |

18 |

19 |

20 |

22 |

24 |

25 |

28 |

30 |

32 |

35 |

38 |

40 |

42 |

45 |

48 |

50 |

55 |

60 |

|

3020 |

25 |

28 |

30 |

35 |

38 |

40 |

42 |

45 |

48 |

50 |

55 |

60 |

65 |

70 |

75 |

||||

|

3535 |

35 |

38 |

40 |

42 |

45 |

48 |

50 |

55 |

60 |

65 |

70 |

75 |

80 |

85 |

90 |

||||

|

4545 |

55 |

60 |

65 |

70 |

75 |

80 |

85 |

90 |

95 |

100 |

105 |

110 |

|||||||

GL GE couplings are designed to transmit torque between drive and driven components with zero‑backlash via curved jaw hubs and elastomeric elements, commonly known as spiders. The combination of these components provides dampening and accommodation of misalignment. This product is available in a variety of metals, elastomers and mounting configurations to meet your specific needs. GL GS couplings suitable for horizontal or vertical applications are constructed from a variety of materials, providing a torsionally flexible zero‑backlash platform optimizing the balance between inertia, coupling performance and application requirements. The machined concaved jaws provide a pocket to preload the spider legs, allowing the spiders to articulate freely while accommodating misalignment, minimizing restoring forces, dampen shock and vibration, while providing failsafe zero‑backlash torque transmission. The symmetrical relationship of the hubs allows for a variety of accessories to accommodate different shaft distances.

Product detail pictures:

Related Product Guide:

Our concentrate on is always to consolidate and enhance the excellent and service of present solutions, in the meantime regularly develop new products to meet distinctive customers' demands for Manufacturer for Coupling Pin - GE Couplings, Type 1/1, 1a/1a, 1b/1b in AL/Cast/Steel – GOODLUCK , The product will supply to all over the world, such as: Paraguay, Madras, Slovak Republic, All our products are exported to clients in the UK, Germany, France, Spain, the USA, Canada, Iran, Iraq, the Middle East and Africa. Our products are well welcomed by our customers for the high quality, competitive prices and the most favorable styles. We hope to establish business relationship with all customers and bring more beautifu colors for the life.

The company leader recept us warmly, through a meticulous and thorough discussion, we signed a purchase order. Hope to cooperate smoothly