Manufacturer for Sdc Chains - Welded Steel Mill Chains and with Attachments, Welded Steel Drag Chains adn Attachments – GOODLUCK

Manufacturer for Sdc Chains - Welded Steel Mill Chains and with Attachments, Welded Steel Drag Chains adn Attachments – GOODLUCK Detail:

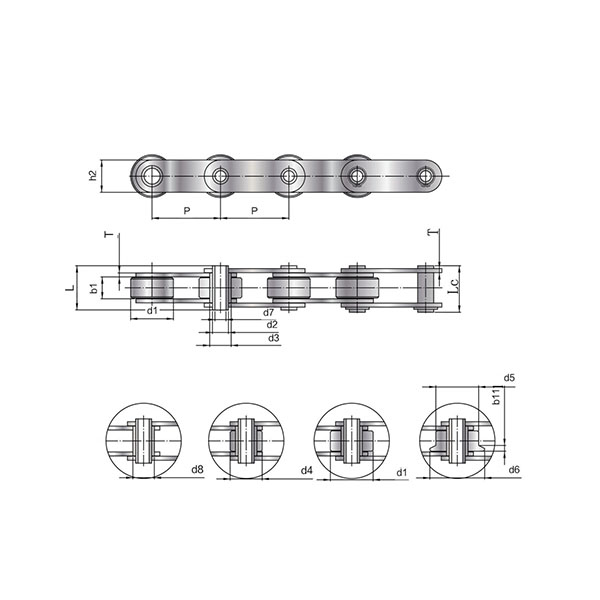

WELDED STEEL MILL CHAINS

|

GL Chain No. |

Pitch |

Outside Barrel dia. |

Pin dia. |

Plate depth |

Approx. Tooth Face at Pitch Line |

Length of Bearing |

Thickness of Plate |

Ultimate tensie strength |

Weight approx. |

|

|

P |

d1(max) |

d2(max) |

h2(max) |

b1(max) |

b2(max) |

S(max) |

Q |

q |

||

|

mm |

mm |

mm |

mm |

mm |

mm |

mm |

kN |

kg/ft |

kg/m |

|

|

WR-78 |

66.27 |

22.23 |

12.70 |

28.40 |

31.75 |

51.00 |

6.40 |

93.40 |

1.90 |

6.23 |

|

WH-78 |

66.27 |

22.23 |

12.70 |

28.40 |

31.75 |

51.00 |

6.40 |

146.00 |

1.90 |

6.23 |

|

WR-82 |

78.10 |

26.97 |

14.35 |

31.80 |

38.10 |

57.40 |

6.40 |

100.10 |

2.28 |

7.48 |

|

WH-82 |

78.10 |

26.97 |

14.35 |

31.80 |

38.10 |

57.40 |

6.40 |

132.00 |

2.28 |

7.48 |

|

WR-124 |

101.60 |

31.75 |

19.05 |

38.10 |

41.28 |

70.30 |

9.70 |

169.00 |

3.62 |

11.88 |

|

WH-124 |

101.60 |

31.75 |

19.05 |

38.10 |

41.28 |

70.30 |

9.70 |

307.00 |

3.62 |

11.88 |

|

WR-111 |

120.90 |

31.75 |

19.05 |

44.45 |

57.15 |

86.20 |

9.70 |

169.00 |

4.17 |

13.68 |

|

WH-111 |

120.90 |

31.75 |

19.05 |

44.45 |

57.15 |

86.20 |

9.70 |

266.70 |

4.17 |

13.68 |

|

WR-106 |

152.40 |

31.75 |

19.05 |

38.10 |

38.10 |

69.85 |

9.70 |

169.00 |

3.00 |

9.84 |

|

WH-106 |

152.40 |

31.75 |

19.05 |

38.10 |

38.10 |

69.85 |

9.70 |

250.00 |

3.00 |

9.84 |

|

WR-132 |

153.67 |

44.45 |

25.40 |

50.80 |

73.00 |

111.00 |

12.70 |

275.80 |

6.43 |

21.10 |

|

WH-132 |

153.67 |

44.45 |

25.40 |

50.80 |

73.00 |

111.00 |

12.70 |

511.00 |

6.43 |

21.10 |

|

WR-150 |

153.67 |

44.45 |

25.40 |

63.50 |

73.00 |

111.00 |

12.70 |

531.00 |

7.74 |

25.39 |

|

WH-150 |

153.67 |

44.45 |

25.40 |

63.50 |

73.00 |

111.00 |

12.70 |

543.00 |

7.74 |

25.39 |

|

WR-155 |

153.67 |

44.45 |

28.57 |

63.50 |

73.00 |

117.48 |

15.88 |

659.00 |

9.00 |

29.53 |

|

WH-155 |

153.67 |

44.45 |

28.57 |

63.50 |

73.00 |

117.48 |

15.88 |

779.00 |

9.00 |

29.53 |

|

WR-157 |

153.67 |

44.45 |

28.57 |

63.50 |

76.20 |

117.48 |

15.88 |

659.00 |

9.10 |

29.86 |

|

WH-157 |

153.67 |

44.45 |

28.57 |

63.50 |

76.20 |

117.48 |

15.88 |

779.00 |

9.10 |

29.86 |

|

WR-159 |

155.575 |

48.26 |

31.75 |

76.20 |

69.85 |

117.48 |

15.88 |

823.00 |

11.80 |

38.71 |

|

WH-159 |

155.575 |

48.26 |

31.75 |

76.20 |

69.85 |

117.48 |

15.88 |

935.00 |

11.80 |

38.71 |

|

WR-200 |

155.575 |

48.26 |

31.75 |

63.50 |

69.85 |

117.48 |

15.88 |

823.00 |

10.00 |

32.81 |

|

WH-200 |

155.575 |

48.26 |

31.75 |

63.50 |

69.85 |

117.48 |

15.88 |

84600 |

10.00 |

32.81 |

|

GL Chain No. |

Pitch |

Outside Barrel dia. |

Pin dia. |

Plate depth |

Approx. Tooth Face at Pitch Line |

Length of Bearing |

Thickness of Plate |

Ultimate tensie strength |

Weight approx. |

|

|

P |

d1(max) |

d2(max) |

h2(max) |

b1(max) |

b2(max) |

S(max) |

Q |

q |

||

|

mm |

mm |

mm |

mm |

mm |

mm |

mm |

kN |

kg/ft |

kg/m |

|

|

WR-78XHD |

66.95 |

25.40 |

14.29 |

31.75 |

25.40 |

50.80 |

9.50 |

133.00 |

2.82 |

9.25 |

|

WH-78XHD |

66.95 |

25.40 |

14.29 |

31.75 |

25.40 |

50.80 |

9.50 |

160.00 |

2.82 |

9.25 |

|

WR-82XHD |

78.10 |

31.75 |

19.05 |

38.10 |

28.60 |

60.90 |

9.70 |

144.80 |

3.85 |

12.84 |

|

WH-82XHD |

78.10 |

31.75 |

19.05 |

38.10 |

28.60 |

60.90 |

9.70 |

253.00 |

3.85 |

12.84 |

|

WR-124XHD |

103.20 |

44.45 |

25.40 |

50.80 |

38.10 |

76.20 |

12.70 |

378.00 |

6.73 |

21.82 |

|

WH-124XHD |

103.20 |

44.45 |

25.40 |

50.80 |

38.10 |

76.20 |

12.70 |

542.00 |

6.73 |

21.82 |

|

WR-106XHD |

153.67 |

44.45 |

25.40 |

50.80 |

38.10 |

76.20 |

12.70 |

378.00 |

5.52 |

17.90 |

|

WH-106XHD |

153.67 |

44.45 |

25.40 |

50.80 |

38.10 |

76.20 |

12.70 |

542.00 |

5.52 |

17.90 |

|

WR-132XHD |

153.67 |

44.45 |

25.40 |

50.80 |

76.20 |

118.60 |

15.88 |

534.00 |

7.49 |

24.29 |

|

WH-132XHD |

153.67 |

44.45 |

25.40 |

50.80 |

76.20 |

118.60 |

15.88 |

543.00 |

7.49 |

24.29 |

STRAIGNTH BAR WELDED STEEL MILL CHAINS

|

GL Chain No. |

Pitch |

Outside Barrel dia. |

Pin dia. |

Length of Bearing |

Approx. Tooth Face at Pitch Line |

Plate depth |

Thickness of Plate |

Ultimate tensie strength |

Weight approx. |

|

|

P |

d1(max) |

d2(max) |

X(min) |

A(max) |

H(max) |

T(max) |

Q |

q |

||

|

mm |

mm |

mm |

mm |

mm |

mm |

mm |

kN |

kg/ft |

kg/m |

|

|

WRC-78 |

66.27 |

21.336 |

12.70 |

50.80 |

25.40 |

31.75 |

6.35 |

120 |

1.95 |

6.40 |

|

WRC-131 |

78.10 |

31.75 |

19.05 |

57.15 |

25.40 |

38.10 |

9.50 |

224 |

3.08 |

10.10 |

|

WRC-124 |

101.60 |

31.75 |

19.05 |

71.00 |

38.10 |

38.10 |

9.50 |

224 |

3.62 |

11.88 |

|

WRC-111 |

120.90 |

31.75 |

19.05 |

86.20 |

44.45. |

44.45 |

9.50 |

224 |

4.17 |

13.68 |

|

WRC-110 |

152.40 |

31.75 |

19.05 |

86.20 |

38.10 |

38.10 |

9.70 |

224 |

3.26 |

10.70 |

|

WRC-132 |

153.67 |

44.45 |

25.40 |

111.90 |

69.85 |

50.80 |

12.70 |

380 |

6.40 |

21.00 |

|

WRC-150 |

153.67 |

44.45 |

25.40 |

111.90 |

69.85 |

63.50 |

12.70 |

534 |

7.40 |

24.28 |

|

GL Chain No. |

Pitch |

Outside Barrel dia. |

Pin dia. |

Length of Bearing |

Approx. Tooth Face at Pitch Line |

Plate depth |

Thickness of Plate |

Ultimate tensie strength |

Weight approx. |

|||||||||

|

P |

d1(max) |

d2(max) |

X(min) |

A(max) |

H(max) |

T(max) |

Q |

q |

||||||||||

|

mm |

mm |

mm |

mm |

mm |

mm |

mm |

kN |

kg/ft |

kg/m |

|||||||||

|

WRC-82XHD |

78.10 |

31.75 |

19.05 |

60.33 |

28.58 |

38.10 |

9.50 |

224 |

3.86 |

12.66 |

||||||||

|

WRC-124XHD |

103.20 |

41.28 |

25.40 |

76.20 |

38.10 |

50.80 |

12.70 |

378 |

6.65 |

21.82 |

||||||||

|

WRC-110XHD |

153.67 |

44.45 |

25.40 |

76.20 |

38.10 |

50.80 |

12.70 |

378 |

5.36 |

17.59 |

||||||||

|

WRC-132XHD |

153.67 |

44.45 |

25.40 |

118.27 |

69.85 |

50.80 |

15.88 |

534 |

7.10 |

23.29 |

||||||||

ATTAVHMENT FOR WELDED STEEL MILL CHAINS

|

GL Chain No. |

G |

H |

J K |

M |

N |

0 |

||||||||||

|

mm |

mm |

mm |

mm |

mm |

mm |

mm |

||||||||||

|

WR-78 |

22.23 |

31.75 |

6.35 |

12.70 |

50.80 |

31.75 |

9.53 |

|||||||||

|

WR-78XHD |

22.23 |

31.75 |

6.35 |

12.70 |

50.80 |

31.75 |

9.53 |

|||||||||

|

WR-82 |

22.23 |

38.10 |

6.35 |

15.88 |

60.33 |

44.45 |

9.53 |

|||||||||

|

WR-82XHD |

28.58 |

38.10 |

9.53 |

15.88 |

60.33 |

44.45 |

9.53 |

|||||||||

|

WR-124 |

28.58 |

50.80 |

9.53 |

15.88 |

66.66 |

44.45 |

9.53 |

|||||||||

|

WR-124XHD |

38.10 |

50.80 |

12.70 |

19.05 |

66.68 |

44.45 |

12.70 |

|||||||||

|

WR-111 |

31.75 |

53.98 |

9.53 |

15.88 |

79.38 |

44.45 |

9.53 |

|||||||||

|

WR-132 |

38.10 |

76.20 |

12.70 |

22.23 |

95.25 |

50.80 |

12.70 |

|||||||||

|

WR-132XHD |

38.10 |

76.20 |

12.70 |

22.23 |

95.25 |

50.80 |

12.70 |

|||||||||

|

GL Chain No. |

G |

H |

J |

K |

M |

N |

P |

0 |

|

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

|

|

WR-78 |

22.23 |

20.64 |

6.35 |

12.70 |

50.80 |

53.98 |

28.58 |

9.35 |

|

WR-78XHD |

22.23 |

20.64 |

6.35 |

12.70 |

50.80 |

53.98 |

28.58 |

9.53 |

|

WR-82 |

22.23 |

12.70 |

6.35 |

15.88 |

53.98 |

57.15 |

31.75 |

9.53 |

|

WR-82XHD |

28.58 |

12.70 |

9.53 |

15.88 |

60.33 |

57.15 |

31.75 |

9.53 |

|

WR-124 |

28.58 |

22.23 |

9.53 |

15.88 |

66.68 |

76.20 |

49.21 |

9.53 |

|

WR-124XHD |

38.10 |

22.23 |

12.70 |

19.05 |

66.68 |

101.60 |

49.21 |

12.70 |

|

WR-111 |

31.75 |

25.40 |

9.53 |

19.05 |

79.38 |

101.60 |

58.74 |

9.53 |

|

WR-132 |

38.10 |

41.28 |

12.70 |

19.05 |

95.25 |

107.95 |

69.85 |

12.70 |

|

WR-132XHD |

38.10 |

41.28 |

12.70 |

22.23 |

95.25 |

107.95 |

69.85 |

12.70 |

|

WR-150 |

44.45 |

41.28 |

12.70 |

22.23 |

95.25 |

107.95 |

69.85 |

12.70 |

This chain that we offer exceeds in quality, working life, and strength. Additionally, our chain is extremely durable, offers low maintenance, and is supplied at a great price! Something that is notable about this chain is that each and every component has been heat-treated and constructed using high-quality steel alloy to further increase the overall working life and strength of the chain. welded steel chain is often recommended for most conveying, drive, and elevating applications where a high-strength and durable steel roller-less chain is required. Some of the applications where chain is most commonly found are; heavy-duty conveyors, forest products, grain handling, pulp and paper, and sugar processing.

Product detail pictures:

Related Product Guide:

Being supported by an highly developed and skilled IT group, we could offer you technical support on pre-sales & after-sales support for Manufacturer for Sdc Chains - Welded Steel Mill Chains and with Attachments, Welded Steel Drag Chains adn Attachments – GOODLUCK , The product will supply to all over the world, such as: Nepal, Nepal, Madras, Now the competition in this field is very fierce; but we will still offer best quality, reasonable price and most considerate service in an endeavor to achieve win-win goal. "Change for the better!" is our slogan, which means "A better world is before us, so let's enjoy it!" Change for the better! Are you ready?

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!