Manufacturer for Steel Sprockets - Stock Bore Sprockets per Asian Standard – GOODLUCK

Manufacturer for Steel Sprockets - Stock Bore Sprockets per Asian Standard – GOODLUCK Detail:

| NK15B | |

| SPROCKETS | mm |

| Tooth width (T) | 2.0 |

| CHAIN | mm |

| Pitch (P) | 4.7625 |

| Internal width | 2.38 |

| Roller Φ (Dr) | 2.48 |

|

Type |

Teeth |

Do |

Dp |

Bored |

BD |

BL |

wt |

Material |

||

|

Stock |

Min |

Max |

||||||||

|

NK15B |

11 |

19.0 |

16.90 |

4 |

5 |

7 |

11 |

10 |

9 |

C45 Solid |

|

12 |

20.5 |

18.40 |

4 |

5 |

8 |

12 |

10 |

10 |

||

|

13 |

22.0 |

19.90 |

4 |

5 |

9 |

14 |

10 |

14 |

||

|

14 |

23.5 |

21.40 |

6 |

7 |

10 |

15 |

12 |

17 |

||

|

15 |

25.0 |

22.91 |

6 |

7 |

12 |

17 |

12 |

22 |

||

|

16 |

26.5 |

24.41 |

8 |

9 |

12 |

18 |

1Z |

23 |

||

|

17 |

28.0 |

25.92 |

8 |

9 |

14 |

20 |

14 |

32 |

||

|

18 |

295 |

27.43 |

8 |

9 |

14 |

22 |

14 |

40 |

||

|

19 |

3L0 |

28.93 |

8 |

9 |

15 |

23 |

14 |

44 |

||

|

20 |

32.5 |

30.44 |

8 |

9 |

15 |

24 |

14 |

49 |

||

|

21 |

34.0 |

31.95 |

8 |

9 |

17 |

26 |

14 |

57 |

||

|

22 |

355 |

33.46 |

8 |

9 |

17 |

27 |

14 |

62 |

||

|

23 |

37.5 |

34.98 |

8 |

9 |

17 |

28 |

14 |

68 |

||

|

24 |

39-0 |

36.49 |

8 |

9 |

20 |

30 |

16 |

88 |

||

|

25 |

405 |

38.00 |

8 |

9 |

20 |

32 |

16 |

100 |

||

|

26 |

42.0 |

39.51 |

10 |

11 |

22 |

33 |

16 |

104 |

||

|

27 |

43.5 |

41.02 |

10 |

11 |

25 |

35 |

16 |

117 |

||

|

28 |

45,0 |

42.54 |

10 |

11 |

25 |

37 |

16 |

131 |

||

|

29 |

46,5 |

44.05 |

10 |

11 |

25 |

38 |

16 |

139 |

||

|

30 |

48.0 |

45.56 |

10 |

11 |

25 |

39 |

16 |

147 |

||

|

31 |

49,5 |

47.08 |

10 |

11 |

25 |

40 |

18 |

175 |

||

|

32 |

SL0 |

48.59 |

10 |

11 |

25 |

40 |

18 |

176 |

||

|

33 |

52.5 |

50.10 |

10 |

11 |

25 |

40 |

18 |

178 |

||

|

34 |

54.0 |

51.62 |

10 |

11 |

25 |

40 |

18 |

180 |

||

|

35 |

55.5 |

53.13 |

10 |

11 |

25 |

40 |

18 |

182 |

||

NK25B

| SPROCKETS | mm |

| Tooth width (T) | 2.8 |

| CHAIN | mm |

| Pitch (P) | 6.35 |

| Internal width | 3.18 |

| Roller Φ (Dr) | 3.3 |

|

Type |

Teeth |

Do |

Dp |

Bored |

BD |

BL |

wt |

Material |

||

|

Stock |

Min |

Max |

g |

|||||||

| NK25B |

10 |

23 |

2055 |

6.5 |

8.5 |

8.5 |

14 |

IS |

30 |

C45 Solid |

|

11 |

25 |

22.54 |

6.5 |

8.5 |

8.5 |

15 |

15 |

30 |

||

|

12 |

28 |

24.53 |

7.5 |

9.5 |

9.5 |

15 |

15 |

30 |

||

|

13 |

30 |

2653 |

7.5 |

9.5 |

10 |

18 |

15 |

50 |

||

|

14 |

32 |

2854 |

7.5 |

9.5 |

10 |

20 |

IS |

50 |

||

|

15 |

34 |

3054 |

75 |

9.5 |

10 |

20 |

IS |

50 |

||

|

16 |

36 |

3255 |

95 |

11.5 |

12 |

25 |

15 |

60 |

||

|

17 |

38 |

34S6 |

9.5 |

11.5 |

12 |

25 |

IS |

70 |

||

|

18 |

40 |

3657 |

9.5 |

115 |

12 |

25 |

15 |

70 |

||

|

19 |

42 |

3858 |

9.5 |

11.5 |

16 |

28 |

15 |

80 |

||

|

20 |

44 |

40.59 |

9.5 |

11.5 |

16 |

28 |

15 |

80 |

||

|

21 |

46 |

42.61 |

95 |

11.5 |

16 |

28 |

15 |

90 |

||

|

22 |

48 |

44.65 |

9.5 |

11.5 |

16 |

30 |

IS |

100 |

||

|

23 |

50 |

46.63 |

9.5 |

11.5 |

16 |

30 |

IS |

110 |

||

|

24 |

52 |

48.6S |

9.5 |

11.5 |

16 |

30 |

IS |

120 |

||

|

25 |

54 |

50.66 |

9S |

11.5 |

20 |

35 |

IS |

140 |

||

|

26 |

56 |

52.68 |

95 |

11.5 |

20 |

35 |

IS |

140 |

||

|

27 |

58 |

54.70 |

95 |

11.5 |

20 |

35 |

15 |

150 |

||

|

28 |

60 |

56.71 |

9.5 |

11.5 |

20 |

35 |

IS |

150 |

||

|

29 |

62 |

5873 |

9,5 |

11.5 |

20 |

35 |

15 |

160 |

||

|

30 |

64 |

60.75 |

9S |

11.5 |

20 |

35 |

15 |

160 |

||

|

31 |

66 |

62.77 |

10.5 |

12.5 |

22 |

40 |

20 |

200 |

||

|

32 |

68 |

64.78 |

10.5 |

12.5 |

22 |

40 |

20 |

200 |

||

|

33 |

70 |

66.80 |

10.5 |

12.5 |

22 |

40 |

20 |

210 |

||

|

34 |

72 |

68.82 |

10.5 |

12.5 |

22 |

40 |

20 |

210 |

||

|

35 |

74 |

70^4 |

10.5 |

12.5 |

22 |

40 |

20 |

210 |

||

|

36 |

76 |

72.86 |

10.5 |

12.5 |

22 |

40 |

20 |

220 |

||

|

37 |

78 |

74.88 |

10,5 |

12.5 |

22 |

3 |

20 |

260 |

||

|

38 |

80 |

76.90 |

10.5 |

12.5 |

22 |

40 |

20 |

260 |

||

|

39 |

82 |

78.91 |

10.5 |

12.5 |

22 |

40 |

20 |

270 |

||

|

40 |

84 |

80.93 |

10.5 |

12.5 |

22 |

40 |

20 |

270 |

||

|

41 |

87 |

82.95 |

10.5 |

12.5 |

30 |

50 |

20 |

320 |

||

|

42 |

89 |

84.97 |

10.5 |

12.5 |

30 |

SO |

20 |

320 |

||

|

43 |

91 |

86.99 |

10.5 |

12.5 |

30 |

50 |

20 |

400 |

||

|

44 |

93 |

89.01 |

10.5 |

12.5 |

30 |

50 |

20 |

410 |

||

|

45 |

95 |

91.03 |

10.5 |

12.5 |

30 |

50 |

20 |

410 |

||

|

4S |

101 |

97.09 |

10.5 |

12.5 |

30 |

50 |

20 |

430 |

||

|

50 |

105 |

10113 |

10.5 |

12.5 |

30 |

50 |

20 |

460 |

||

|

54 |

113 |

10921 |

10.5 |

12.5 |

30 |

50 |

20 |

470 |

||

|

60 |

125 |

12133 |

10.5 |

12.5 |

30 |

50 |

20 |

510 |

||

|

65 |

135 |

13L43 |

11.5 |

13.5 |

30 |

50 |

20 |

720 |

||

|

70 |

145 |

14154 |

11.5 |

13.5 |

30 |

50 |

20 |

770 |

||

|

75 |

1S5 |

151.64 |

11.5 |

13.5 |

30 |

50 |

20 |

820 |

||

|

80 |

165 |

161.74 |

11.5 |

13.5 |

30 |

50 |

20 |

880 |

NK35B

| SPROCKETS | mm |

| Tooth width (T) | 4.3 |

| CHAIN | mm |

| Pitch (P) | 9.525 |

| Internal width | 4.78 |

| Roller Φ (Dr) | 5.08 |

|

Type |

Teeth |

Do |

Dp |

Bored |

BD |

BL |

wt |

Material |

||

|

Stock |

Min |

Max |

||||||||

|

NK35B |

9 |

32 |

27.85 |

85 |

10.5 |

11 |

★21.5 |

20 |

0.06 |

C45 Solid |

|

10 |

34 |

30.82 |

85 |

105 |

12 |

★24.5 |

20 |

0.08 |

||

|

11 |

38 |

33.81 |

95 |

115 |

14 |

★27 |

20 |

0.09 |

||

|

12 |

41 |

36,81 |

9S |

11.5 |

16 |

★50.5 |

20 |

042 |

||

|

13 |

44 |

39.80 |

95 |

11.5 |

18 |

★32 |

20 |

0.12 |

||

|

14 |

47 |

42.81 |

9_5 |

11.5 |

18 |

32 |

20 |

0.12 |

||

|

15 |

51 |

45.81 |

95 |

11.5 |

20 |

35 |

20 |

0.16 |

||

|

16 |

54 |

48.82 |

95 |

11.5 |

20 |

37 |

20 |

0.19 |

||

|

17 |

57 |

51.84 |

115 |

13S |

25 |

41 |

20 |

022 |

||

|

18 |

60 |

54,85 |

115 |

13.5 |

25 |

44 |

20 |

0.25 |

||

|

19 |

63 |

57.87 |

115 |

135 |

28 |

47 |

20 |

0.28 |

||

|

20 |

66 |

60.89 |

115 |

13.5 |

30 |

50 |

20 |

0.32 |

||

|

21 |

69 |

63.91 |

115 |

135 |

32 |

53 |

20 |

036 |

||

|

22 |

72 |

6&93 |

115 |

13.5 |

35 |

56 |

20 |

0.37 |

||

|

23 |

75 |

69.95 |

115 |

135 |

38 |

60 |

20 |

0.38 |

||

|

24 |

78 |

72.97 |

115 |

13.5 |

32 |

53 |

22 |

0.43 |

||

|

25 |

81 |

76.00 |

115 |

13.5 |

32 |

53 |

22 |

0.44 |

||

|

26 |

84 |

79.02 |

115 |

133 |

32 |

53 |

22 |

0.45 |

||

|

27 |

87 |

82.05 |

115 |

135 |

32 |

53 |

22 |

0.46 |

||

|

28 |

90 |

8S.07 |

113 |

13.5 |

32 |

53 |

22 |

0.48 |

||

|

29 |

93 |

8810 |

115 |

13S |

32 |

53 |

22 |

0.49 |

||

|

30 |

96 |

91.12 |

115 |

13.5 |

32 |

53 |

22 |

051 |

||

|

31 |

99 |

94.15 |

115 |

135 |

32 |

S3 |

22 |

053 |

||

|

32 |

102 |

97.18 |

115 |

13.5 |

32 |

53 |

22 |

0.54 |

||

|

33 |

105 |

100.20 |

115 |

135 |

32 |

53 |

22 |

056 |

||

|

34 |

109 |

103.23 |

115 |

135 |

32 |

53 |

22 |

0.57 |

||

|

35 |

112 |

106.26 |

115 |

13.5 |

32 |

S3 |

22 |

0.59 |

||

|

36 |

115 |

109.29 |

125 |

145 |

32 |

53 |

22 |

0.61 |

||

|

37 |

118 |

112.31 |

125 |

14.5 |

42 |

63 |

25 |

0.80 |

||

|

38 |

121 |

115.34 |

125 |

145 |

42 |

63 |

25 |

0.82 |

||

|

39 |

124 |

118.37 |

125 |

145 |

42 |

63 |

25 |

0.84 |

||

|

40 |

127 |

121.40 |

125 |

143 |

42 |

63 |

25 |

0.85 |

||

|

41 |

130 |

124.43 |

16 |

18 |

42 |

63 |

25 |

0.91 |

Fe360 Welding

|

|

|

42 |

133 |

127.46 |

16 |

18 |

42 |

63 |

25 |

0.93 |

||

|

43 |

136 |

130.49 |

16 |

18 |

42 |

63 |

25 |

0.95 |

||

|

44 |

139 |

133.52 |

16 |

18 |

42 |

63 |

25 |

0.97 |

||

|

45 |

142 |

136.55 |

16 |

18 |

42 |

63 |

25 |

1.00 |

||

|

46 |

145 |

139.58 |

16 |

18 |

42 |

63 |

25 |

1.01 |

||

|

47 |

148 |

142.61 |

16 |

18 |

42 |

63 |

25 |

1.03 |

||

|

48 |

151 |

145.64 |

16 |

18 |

42 |

63 |

25 |

1.05 |

||

|

SO |

157 |

151.70 |

16 |

18 |

42 |

63 |

25 |

1.07 |

||

|

53 |

166 |

160.78 |

16 |

18 |

42 |

63 |

25 |

1.09 |

||

|

54 |

169 |

163.81 |

16 |

18 |

42 |

63 |

25 |

1.10 |

||

|

55 |

172 |

166.85 |

16 |

18 |

42 |

63 |

25 |

1.25 |

||

|

60 |

187 |

182.00 |

16 |

18 |

42 |

63 |

25 |

1.30 |

||

|

64 |

200 |

194.12 |

16 |

18 |

42 |

63 |

25 |

1,46 |

||

|

65 |

203 |

197.15 |

16 |

18 |

45 |

68 |

25 |

1.67 |

||

|

70 |

218 |

212.30 |

16 |

18 |

45 |

68 |

25 |

1.80 |

||

|

75 |

233 |

227.46 |

16 |

18 |

45 |

68 |

25 |

1.90 |

||

|

80 |

248 |

242.61 |

16 |

18 |

45 |

68 |

25 |

2.40 |

| Teeth | s | GD |

| 9 | 4.4 | 17 |

| 10 | 20 | |

| 11 | 23 | |

| 12 | 26 | |

| 13 | 29 |

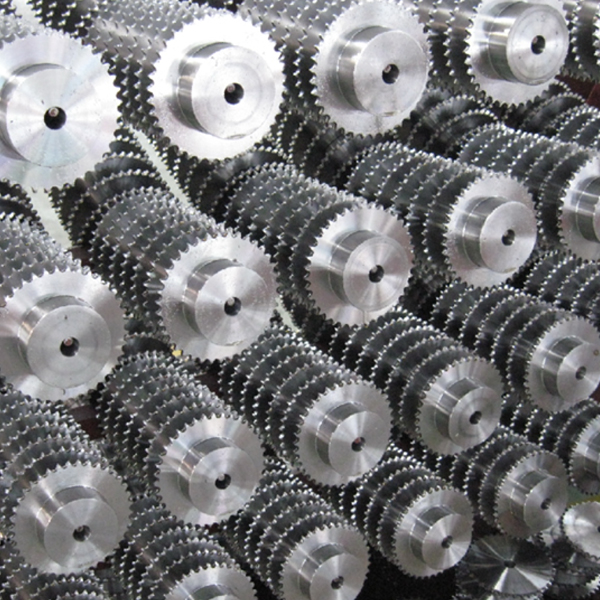

GL offers sprockets with an emphasis on precision engineering and perfect quality. Our stock Pilot Bore hole (PB) plate wheel and sprockets are ideal for being machined to the bore which customers desire need as different shaft diamater.

We offer Type A (hub-less) plate wheels from #25 (0.250 “), #35 (0.375 “) , #40 (0.500 “) till #240(3″) pitches in stock. The finished plate wheels are some in stock.

We also offer Type B(hub) sprockets from #25 (0.250 “), #35 (0.375 “), #40 (0.500 “), #41 (0.500 “), #50 (0.625 “) , #50 (0.625 “) till #240(3″) pitch in stock. The finished sprockets are some in stock.

Teeth of PB plate wheel and sprockets hardened are avilable.

Material are made of steel C45.

We also offer PB plate wheels and sprockets in stainless steel SS304 for these sizes.

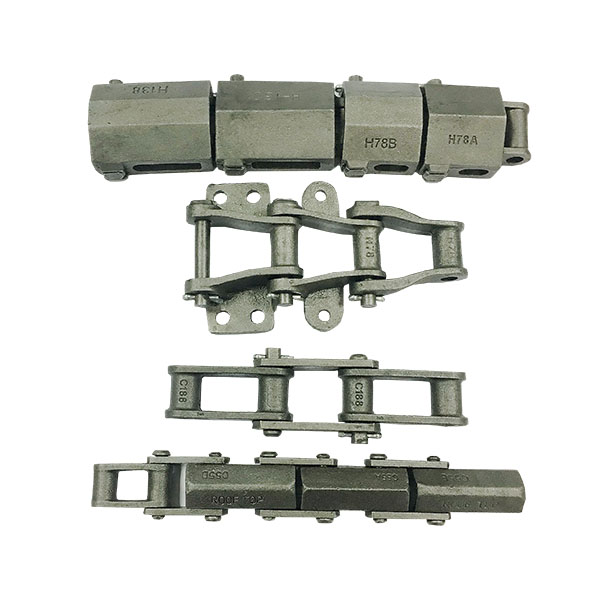

Product detail pictures:

Related Product Guide:

Our advantages are lessen charges,dynamic income team,specialized QC,sturdy factories,premium quality services for Manufacturer for Steel Sprockets - Stock Bore Sprockets per Asian Standard – GOODLUCK , The product will supply to all over the world, such as: Mexico, Adelaide, moldova, With the goal of "zero defect". To care for the environment, and social returns, care employee social responsibility as own duty. We welcome friends from all over the world to visit and guide us so that we can achieve the win-win goal together.

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.