Manufacturer for Steel Sprockets - Stock Bore Sprockets per Asian Standard – GOODLUCK

Manufacturer for Steel Sprockets - Stock Bore Sprockets per Asian Standard – GOODLUCK Detail:

| NK15B | |

| SPROCKETS | mm |

| Tooth width (T) | 2.0 |

| CHAIN | mm |

| Pitch (P) | 4.7625 |

| Internal width | 2.38 |

| Roller Φ (Dr) | 2.48 |

|

Type |

Teeth |

Do |

Dp |

Bored |

BD |

BL |

wt |

Material |

||

|

Stock |

Min |

Max |

||||||||

|

NK15B |

11 |

19.0 |

16.90 |

4 |

5 |

7 |

11 |

10 |

9 |

C45 Solid |

|

12 |

20.5 |

18.40 |

4 |

5 |

8 |

12 |

10 |

10 |

||

|

13 |

22.0 |

19.90 |

4 |

5 |

9 |

14 |

10 |

14 |

||

|

14 |

23.5 |

21.40 |

6 |

7 |

10 |

15 |

12 |

17 |

||

|

15 |

25.0 |

22.91 |

6 |

7 |

12 |

17 |

12 |

22 |

||

|

16 |

26.5 |

24.41 |

8 |

9 |

12 |

18 |

1Z |

23 |

||

|

17 |

28.0 |

25.92 |

8 |

9 |

14 |

20 |

14 |

32 |

||

|

18 |

295 |

27.43 |

8 |

9 |

14 |

22 |

14 |

40 |

||

|

19 |

3L0 |

28.93 |

8 |

9 |

15 |

23 |

14 |

44 |

||

|

20 |

32.5 |

30.44 |

8 |

9 |

15 |

24 |

14 |

49 |

||

|

21 |

34.0 |

31.95 |

8 |

9 |

17 |

26 |

14 |

57 |

||

|

22 |

355 |

33.46 |

8 |

9 |

17 |

27 |

14 |

62 |

||

|

23 |

37.5 |

34.98 |

8 |

9 |

17 |

28 |

14 |

68 |

||

|

24 |

39-0 |

36.49 |

8 |

9 |

20 |

30 |

16 |

88 |

||

|

25 |

405 |

38.00 |

8 |

9 |

20 |

32 |

16 |

100 |

||

|

26 |

42.0 |

39.51 |

10 |

11 |

22 |

33 |

16 |

104 |

||

|

27 |

43.5 |

41.02 |

10 |

11 |

25 |

35 |

16 |

117 |

||

|

28 |

45,0 |

42.54 |

10 |

11 |

25 |

37 |

16 |

131 |

||

|

29 |

46,5 |

44.05 |

10 |

11 |

25 |

38 |

16 |

139 |

||

|

30 |

48.0 |

45.56 |

10 |

11 |

25 |

39 |

16 |

147 |

||

|

31 |

49,5 |

47.08 |

10 |

11 |

25 |

40 |

18 |

175 |

||

|

32 |

SL0 |

48.59 |

10 |

11 |

25 |

40 |

18 |

176 |

||

|

33 |

52.5 |

50.10 |

10 |

11 |

25 |

40 |

18 |

178 |

||

|

34 |

54.0 |

51.62 |

10 |

11 |

25 |

40 |

18 |

180 |

||

|

35 |

55.5 |

53.13 |

10 |

11 |

25 |

40 |

18 |

182 |

||

NK25B

| SPROCKETS | mm |

| Tooth width (T) | 2.8 |

| CHAIN | mm |

| Pitch (P) | 6.35 |

| Internal width | 3.18 |

| Roller Φ (Dr) | 3.3 |

|

Type |

Teeth |

Do |

Dp |

Bored |

BD |

BL |

wt |

Material |

||

|

Stock |

Min |

Max |

g |

|||||||

| NK25B |

10 |

23 |

2055 |

6.5 |

8.5 |

8.5 |

14 |

IS |

30 |

C45 Solid |

|

11 |

25 |

22.54 |

6.5 |

8.5 |

8.5 |

15 |

15 |

30 |

||

|

12 |

28 |

24.53 |

7.5 |

9.5 |

9.5 |

15 |

15 |

30 |

||

|

13 |

30 |

2653 |

7.5 |

9.5 |

10 |

18 |

15 |

50 |

||

|

14 |

32 |

2854 |

7.5 |

9.5 |

10 |

20 |

IS |

50 |

||

|

15 |

34 |

3054 |

75 |

9.5 |

10 |

20 |

IS |

50 |

||

|

16 |

36 |

3255 |

95 |

11.5 |

12 |

25 |

15 |

60 |

||

|

17 |

38 |

34S6 |

9.5 |

11.5 |

12 |

25 |

IS |

70 |

||

|

18 |

40 |

3657 |

9.5 |

115 |

12 |

25 |

15 |

70 |

||

|

19 |

42 |

3858 |

9.5 |

11.5 |

16 |

28 |

15 |

80 |

||

|

20 |

44 |

40.59 |

9.5 |

11.5 |

16 |

28 |

15 |

80 |

||

|

21 |

46 |

42.61 |

95 |

11.5 |

16 |

28 |

15 |

90 |

||

|

22 |

48 |

44.65 |

9.5 |

11.5 |

16 |

30 |

IS |

100 |

||

|

23 |

50 |

46.63 |

9.5 |

11.5 |

16 |

30 |

IS |

110 |

||

|

24 |

52 |

48.6S |

9.5 |

11.5 |

16 |

30 |

IS |

120 |

||

|

25 |

54 |

50.66 |

9S |

11.5 |

20 |

35 |

IS |

140 |

||

|

26 |

56 |

52.68 |

95 |

11.5 |

20 |

35 |

IS |

140 |

||

|

27 |

58 |

54.70 |

95 |

11.5 |

20 |

35 |

15 |

150 |

||

|

28 |

60 |

56.71 |

9.5 |

11.5 |

20 |

35 |

IS |

150 |

||

|

29 |

62 |

5873 |

9,5 |

11.5 |

20 |

35 |

15 |

160 |

||

|

30 |

64 |

60.75 |

9S |

11.5 |

20 |

35 |

15 |

160 |

||

|

31 |

66 |

62.77 |

10.5 |

12.5 |

22 |

40 |

20 |

200 |

||

|

32 |

68 |

64.78 |

10.5 |

12.5 |

22 |

40 |

20 |

200 |

||

|

33 |

70 |

66.80 |

10.5 |

12.5 |

22 |

40 |

20 |

210 |

||

|

34 |

72 |

68.82 |

10.5 |

12.5 |

22 |

40 |

20 |

210 |

||

|

35 |

74 |

70^4 |

10.5 |

12.5 |

22 |

40 |

20 |

210 |

||

|

36 |

76 |

72.86 |

10.5 |

12.5 |

22 |

40 |

20 |

220 |

||

|

37 |

78 |

74.88 |

10,5 |

12.5 |

22 |

3 |

20 |

260 |

||

|

38 |

80 |

76.90 |

10.5 |

12.5 |

22 |

40 |

20 |

260 |

||

|

39 |

82 |

78.91 |

10.5 |

12.5 |

22 |

40 |

20 |

270 |

||

|

40 |

84 |

80.93 |

10.5 |

12.5 |

22 |

40 |

20 |

270 |

||

|

41 |

87 |

82.95 |

10.5 |

12.5 |

30 |

50 |

20 |

320 |

||

|

42 |

89 |

84.97 |

10.5 |

12.5 |

30 |

SO |

20 |

320 |

||

|

43 |

91 |

86.99 |

10.5 |

12.5 |

30 |

50 |

20 |

400 |

||

|

44 |

93 |

89.01 |

10.5 |

12.5 |

30 |

50 |

20 |

410 |

||

|

45 |

95 |

91.03 |

10.5 |

12.5 |

30 |

50 |

20 |

410 |

||

|

4S |

101 |

97.09 |

10.5 |

12.5 |

30 |

50 |

20 |

430 |

||

|

50 |

105 |

10113 |

10.5 |

12.5 |

30 |

50 |

20 |

460 |

||

|

54 |

113 |

10921 |

10.5 |

12.5 |

30 |

50 |

20 |

470 |

||

|

60 |

125 |

12133 |

10.5 |

12.5 |

30 |

50 |

20 |

510 |

||

|

65 |

135 |

13L43 |

11.5 |

13.5 |

30 |

50 |

20 |

720 |

||

|

70 |

145 |

14154 |

11.5 |

13.5 |

30 |

50 |

20 |

770 |

||

|

75 |

1S5 |

151.64 |

11.5 |

13.5 |

30 |

50 |

20 |

820 |

||

|

80 |

165 |

161.74 |

11.5 |

13.5 |

30 |

50 |

20 |

880 |

NK35B

| SPROCKETS | mm |

| Tooth width (T) | 4.3 |

| CHAIN | mm |

| Pitch (P) | 9.525 |

| Internal width | 4.78 |

| Roller Φ (Dr) | 5.08 |

|

Type |

Teeth |

Do |

Dp |

Bored |

BD |

BL |

wt |

Material |

||

|

Stock |

Min |

Max |

||||||||

|

NK35B |

9 |

32 |

27.85 |

85 |

10.5 |

11 |

★21.5 |

20 |

0.06 |

C45 Solid |

|

10 |

34 |

30.82 |

85 |

105 |

12 |

★24.5 |

20 |

0.08 |

||

|

11 |

38 |

33.81 |

95 |

115 |

14 |

★27 |

20 |

0.09 |

||

|

12 |

41 |

36,81 |

9S |

11.5 |

16 |

★50.5 |

20 |

042 |

||

|

13 |

44 |

39.80 |

95 |

11.5 |

18 |

★32 |

20 |

0.12 |

||

|

14 |

47 |

42.81 |

9_5 |

11.5 |

18 |

32 |

20 |

0.12 |

||

|

15 |

51 |

45.81 |

95 |

11.5 |

20 |

35 |

20 |

0.16 |

||

|

16 |

54 |

48.82 |

95 |

11.5 |

20 |

37 |

20 |

0.19 |

||

|

17 |

57 |

51.84 |

115 |

13S |

25 |

41 |

20 |

022 |

||

|

18 |

60 |

54,85 |

115 |

13.5 |

25 |

44 |

20 |

0.25 |

||

|

19 |

63 |

57.87 |

115 |

135 |

28 |

47 |

20 |

0.28 |

||

|

20 |

66 |

60.89 |

115 |

13.5 |

30 |

50 |

20 |

0.32 |

||

|

21 |

69 |

63.91 |

115 |

135 |

32 |

53 |

20 |

036 |

||

|

22 |

72 |

6&93 |

115 |

13.5 |

35 |

56 |

20 |

0.37 |

||

|

23 |

75 |

69.95 |

115 |

135 |

38 |

60 |

20 |

0.38 |

||

|

24 |

78 |

72.97 |

115 |

13.5 |

32 |

53 |

22 |

0.43 |

||

|

25 |

81 |

76.00 |

115 |

13.5 |

32 |

53 |

22 |

0.44 |

||

|

26 |

84 |

79.02 |

115 |

133 |

32 |

53 |

22 |

0.45 |

||

|

27 |

87 |

82.05 |

115 |

135 |

32 |

53 |

22 |

0.46 |

||

|

28 |

90 |

8S.07 |

113 |

13.5 |

32 |

53 |

22 |

0.48 |

||

|

29 |

93 |

8810 |

115 |

13S |

32 |

53 |

22 |

0.49 |

||

|

30 |

96 |

91.12 |

115 |

13.5 |

32 |

53 |

22 |

051 |

||

|

31 |

99 |

94.15 |

115 |

135 |

32 |

S3 |

22 |

053 |

||

|

32 |

102 |

97.18 |

115 |

13.5 |

32 |

53 |

22 |

0.54 |

||

|

33 |

105 |

100.20 |

115 |

135 |

32 |

53 |

22 |

056 |

||

|

34 |

109 |

103.23 |

115 |

135 |

32 |

53 |

22 |

0.57 |

||

|

35 |

112 |

106.26 |

115 |

13.5 |

32 |

S3 |

22 |

0.59 |

||

|

36 |

115 |

109.29 |

125 |

145 |

32 |

53 |

22 |

0.61 |

||

|

37 |

118 |

112.31 |

125 |

14.5 |

42 |

63 |

25 |

0.80 |

||

|

38 |

121 |

115.34 |

125 |

145 |

42 |

63 |

25 |

0.82 |

||

|

39 |

124 |

118.37 |

125 |

145 |

42 |

63 |

25 |

0.84 |

||

|

40 |

127 |

121.40 |

125 |

143 |

42 |

63 |

25 |

0.85 |

||

|

41 |

130 |

124.43 |

16 |

18 |

42 |

63 |

25 |

0.91 |

Fe360 Welding

|

|

|

42 |

133 |

127.46 |

16 |

18 |

42 |

63 |

25 |

0.93 |

||

|

43 |

136 |

130.49 |

16 |

18 |

42 |

63 |

25 |

0.95 |

||

|

44 |

139 |

133.52 |

16 |

18 |

42 |

63 |

25 |

0.97 |

||

|

45 |

142 |

136.55 |

16 |

18 |

42 |

63 |

25 |

1.00 |

||

|

46 |

145 |

139.58 |

16 |

18 |

42 |

63 |

25 |

1.01 |

||

|

47 |

148 |

142.61 |

16 |

18 |

42 |

63 |

25 |

1.03 |

||

|

48 |

151 |

145.64 |

16 |

18 |

42 |

63 |

25 |

1.05 |

||

|

SO |

157 |

151.70 |

16 |

18 |

42 |

63 |

25 |

1.07 |

||

|

53 |

166 |

160.78 |

16 |

18 |

42 |

63 |

25 |

1.09 |

||

|

54 |

169 |

163.81 |

16 |

18 |

42 |

63 |

25 |

1.10 |

||

|

55 |

172 |

166.85 |

16 |

18 |

42 |

63 |

25 |

1.25 |

||

|

60 |

187 |

182.00 |

16 |

18 |

42 |

63 |

25 |

1.30 |

||

|

64 |

200 |

194.12 |

16 |

18 |

42 |

63 |

25 |

1,46 |

||

|

65 |

203 |

197.15 |

16 |

18 |

45 |

68 |

25 |

1.67 |

||

|

70 |

218 |

212.30 |

16 |

18 |

45 |

68 |

25 |

1.80 |

||

|

75 |

233 |

227.46 |

16 |

18 |

45 |

68 |

25 |

1.90 |

||

|

80 |

248 |

242.61 |

16 |

18 |

45 |

68 |

25 |

2.40 |

| Teeth | s | GD |

| 9 | 4.4 | 17 |

| 10 | 20 | |

| 11 | 23 | |

| 12 | 26 | |

| 13 | 29 |

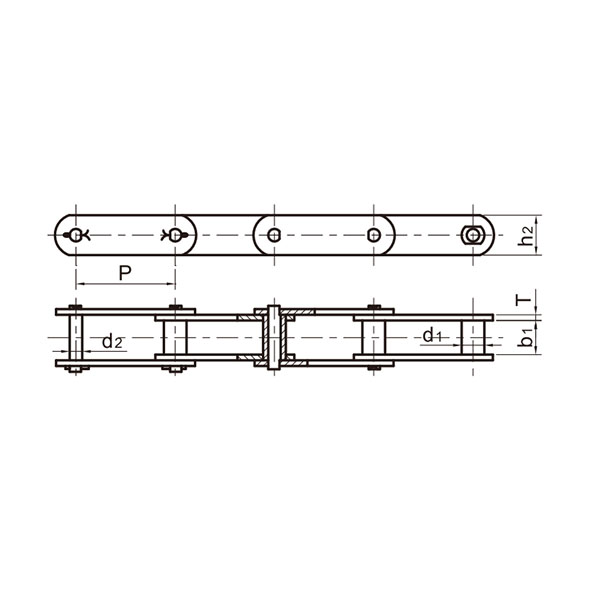

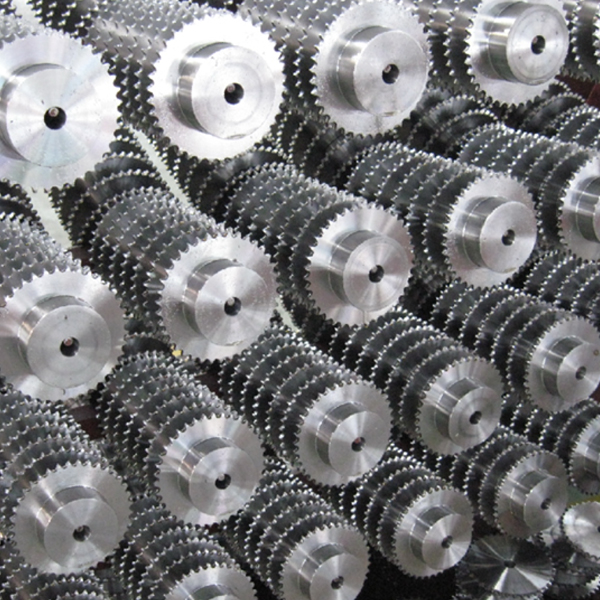

GL offers sprockets with an emphasis on precision engineering and perfect quality. Our stock Pilot Bore hole (PB) plate wheel and sprockets are ideal for being machined to the bore which customers desire need as different shaft diamater.

We offer Type A (hub-less) plate wheels from #25 (0.250 “), #35 (0.375 “) , #40 (0.500 “) till #240(3″) pitches in stock. The finished plate wheels are some in stock.

We also offer Type B(hub) sprockets from #25 (0.250 “), #35 (0.375 “), #40 (0.500 “), #41 (0.500 “), #50 (0.625 “) , #50 (0.625 “) till #240(3″) pitch in stock. The finished sprockets are some in stock.

Teeth of PB plate wheel and sprockets hardened are avilable.

Material are made of steel C45.

We also offer PB plate wheels and sprockets in stainless steel SS304 for these sizes.

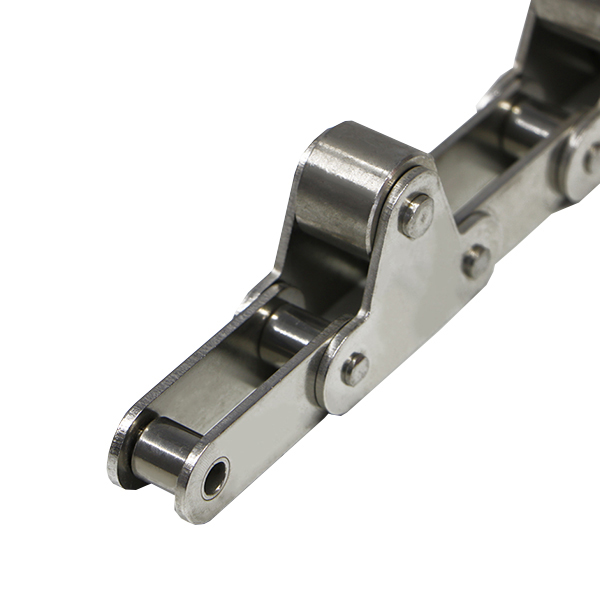

Product detail pictures:

Related Product Guide:

With our leading technology at the same time as our spirit of innovation,mutual cooperation, benefits and advancement, we will build a prosperous future with each other with your esteemed firm for Manufacturer for Steel Sprockets - Stock Bore Sprockets per Asian Standard – GOODLUCK , The product will supply to all over the world, such as: Bangkok, Ecuador, Lesotho, We have a excellent team supplying professional service, prompt reply, timely delivery, excellent quality and best price to our customers. Satisfaction and good credit to every customer is our priority. We are sincerely looking forward to cooperate with customers all over the world. We believe we can satisfy with you. We also warmly welcome customers to visit our company and purchase our products.

On this website, product categories is clear and rich, I can find the product I want very quickly and easily, this is really very good!