Manufacturer of Drag Chain Conveyor - Offset Sidebar Chains for Heavy-duty/ Cranked-Link Transmission Chains – GOODLUCK

Manufacturer of Drag Chain Conveyor - Offset Sidebar Chains for Heavy-duty/ Cranked-Link Transmission Chains – GOODLUCK Detail:

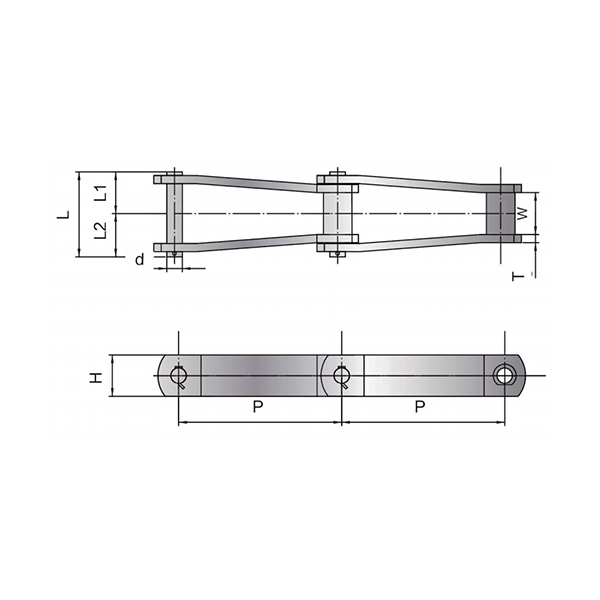

OFFSET SIDEBAR CHAINS(B SERIES)

|

GL Chain No. ISOGB |

Pitch |

Inside width |

Roller dia. |

Plate |

Pin |

Ultimate tensie strength |

Weight approx. |

||

|

Depth |

Thickness |

Length |

dia. |

||||||

|

P |

b1(nom) |

d1(max) |

h2(max) |

C(nom) |

L(max) |

d2(max) |

Q |

q |

|

|

mm |

mm |

mm |

mm |

mm |

mm |

mm |

kN |

kg/m |

|

|

2010 |

63.50 |

38.10 |

31.75 |

47.80 |

7.90 |

90.70 |

15.90 |

250 |

15 |

|

2512 |

77.90 |

39.60 |

41.28 |

60.50 |

9.70 |

103.40 |

19.08 |

340 |

18 |

|

2814 |

88.90 |

38.10 |

44.45 |

60.50 |

12.70 |

117.60 |

22.25 |

470 |

25 |

|

3315 |

103.45 |

49.30 |

45.24 |

63.50 |

14.20 |

134.90 |

23.85 |

550 |

27 |

|

3618 |

114.30 |

52.30 |

57.15 |

79.20 |

14.20 |

141.20 |

27.97 |

760 |

38 |

|

4020 |

127.00 |

69.90 |

63.50 |

91.90 |

15.70 |

168.10 |

31.78 |

990 |

52 |

|

4824 |

152.40 |

76.20 |

76.20 |

104.60 |

19.00 |

187.50 |

38.13 |

1400 |

73 |

|

5628 |

177.80 |

82.60 |

88.90 |

133.40 |

22.40 |

215.90 |

44.48 |

1890 |

108 |

|

WG781 |

78.18 |

38.10 |

33 |

45 |

10 |

97 |

17 |

313.60 |

16 |

|

WG103 |

103.20 |

49.20 |

46 |

60 |

13 |

125.50 |

23 |

539.00 |

26 |

|

WG103H |

103.20 |

49.20 |

46 |

60 |

16 |

135 |

23 |

539.00 |

31 |

|

WG140 |

140.00 |

80.00 |

65 |

90 |

20 |

187 |

35 |

1176.00 |

59.20 |

|

WG10389 |

103.89 |

49.20 |

46 |

70 |

16 |

142 |

26.70 |

1029.00 |

32 |

|

WG9525 |

95.25 |

39.00 |

45 |

65 |

16 |

124 |

23 |

635.00 |

22.25 |

|

WG7900 |

79.00 |

39.20 |

31.50 |

54 |

9.50 |

93.50 |

16.80 |

380.90 |

12.28 |

|

WG7938 |

79.38 |

41.20 |

40 |

57.20 |

9.50 |

100 |

19.50 |

509.00 |

18.70 |

|

W3H |

78.11 |

38.10 |

31.75 |

41.50 |

9.50 |

92.50 |

15.88 |

389.20 |

12.40 |

|

W1602AA |

127.00 |

70.00 |

63.50 |

90 |

16 |

161.20 |

31.75 |

990 |

52.30 |

|

W3 |

78.11 |

38.10 |

31.75 |

38 |

8 |

86.50 |

15.88 |

271.50 |

10.50 |

|

W4 |

103.20 |

49.10 |

44.45 |

54 |

12.70 |

122.20 |

22.23 |

622.50 |

21.00 |

|

W5 |

103.20 |

38.60 |

44.45 |

54 |

12.70 |

111.70 |

22.23 |

622.50 |

19.90 |

Heavy Duty Offset Sidebar Roller Chain

The heavy duty offset sidebar roller chain is designed for drive and traction purposes, and is commonly used on mining equipment, grain processing equipment, as well as equipment sets in steel mills. It is processed with high strength, impact resistance, and wearing resistance, so as to ensure safety in heavy duty applications.1. Made of medium carbon steel, the offset sidebar roller chain undergoes processing steps like heating, bending, as well as cold pressing after annealing.

2. The pin hole is created by impact extrusion, which increases the inner surface smoothness for the hole. Thus, the matching area between the sidebar and the pin is increased, and the pins offer higher protection against heavy loads.

3. The integral heat treatment for the chain plates and rollers ensures high tensile strength. The pins additionally undergo high-frequency induction heating for the surface after integral heat treatment, ensuring high strength, high surface hardness, and wearing resistance as well. The surface carburizing treatment for the bushings or sleeves guarantees high tensile strength, superb surface hardness, and improved impact resistance. These make sure the heavy duty transmission chain has extended service life.

Product detail pictures:

Related Product Guide:

Our organization insists all along the quality policy of "product quality is base of business survival; purchaser gratification is the staring point and ending of an business; persistent improvement is eternal pursuit of staff" as well as the consistent purpose of "reputation 1st, purchaser first" for Manufacturer of Drag Chain Conveyor - Offset Sidebar Chains for Heavy-duty/ Cranked-Link Transmission Chains – GOODLUCK , The product will supply to all over the world, such as: Poland, Saudi Arabia, Poland, Our Company policy is "quality first, to be better and stronger, sustainable development" . Our pursuit goals is "for society, customers, employees, partners and enterprises to seek reasonable benefit". We aspirate to do cooperate with all different the auto parts manufacturers, repair shop, auto peer , then create a beautiful future! Thank you for taking time to browse our website and we would welcome any suggestions you may have that can help us to improve our site.

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.