New Fashion Design for Conveyor Chain Sprocket - Double Sprockets For Two Single Chains per American Standard – GOODLUCK

New Fashion Design for Conveyor Chain Sprocket - Double Sprockets For Two Single Chains per American Standard – GOODLUCK Detail:

Single-Type C-Steel

|

No. Teeth |

Number |

De |

DI |

Dm |

A |

Wt. Lbs. (Approx.) |

|

|

|

Min |

Max. |

|||||||

|

12 |

40C12 |

2.170 |

1/2 |

1 |

139/64 |

11/2 |

.75 |

|

|

13 |

40C13 |

2.330 |

1/2 |

1/16 |

13/4 |

11/2 |

.94 |

|

|

14 |

40C14 |

2.490 |

1/2 |

1/8 |

111/16 |

11/2 |

.91 |

|

|

15 |

40C15 |

2.650 |

1/2 |

1/4 |

17/8 |

11/2 |

1.19 |

|

|

16 |

40C16 |

2.810 |

1/2 |

3/8 |

2 |

11/2 |

1.34 |

|

|

17 |

40C17 |

2.980 |

5/8 |

7/16 |

21/8 |

11/2 |

1.5 |

|

|

18 |

40C18 |

3.140 |

5/8 |

1/2 |

25/16 |

11/2 |

1.8 |

|

★ Has recessed groove in hub for chain clearance.

Double Single-Type A-Steel

|

No. Teeth |

Number |

De |

Dp |

Type |

DI |

L |

c |

E |

B1 |

Wt. (Approx.) |

|

|

|

Min |

Max. |

|||||||||||

|

15 |

DS40A15 |

2.650 |

2.405 |

A |

1/2 |

11/4 |

113/32 |

11/8 |

113/16 |

.284 |

1.2 |

|

|

16 |

DS40A16 |

2.810 |

2.563 |

A |

1/2 |

11/4 |

113/32 |

11/8 |

2 |

.284 |

1.4 |

|

|

17 |

DS40A17 |

2.980 |

2.721 |

A |

1/2 |

15/16 |

113/32 |

11/8 |

21/8 |

.284 |

1.6 |

|

|

18 |

DS40A18 |

3.140 |

2.879 |

A |

1/2 |

11/2 |

113/32 |

11/8 |

25/16 |

.284 |

1.8 |

|

|

19 |

DS40A19 |

3.300 |

3.038 |

A |

5/8 |

111/16 |

113/32 |

11/8 |

21/2 |

.284 |

2.2 |

|

|

20 |

DS40A20 |

3.460 |

3.196 |

A |

5/8 |

13/4 |

113/32 |

11/8 |

25/8 |

.284 |

2.6 |

|

|

21 |

DS40A21 |

3.620 |

3.355 |

A |

5/8 |

13/4 |

113/32 |

11/8 |

225/32 |

.284 |

2.9 |

|

|

22 |

DS40A22 |

3.780 |

3.513 |

A |

5/8 |

113/16 |

113/32 |

11/8 |

215/16 |

.284 |

3.0 |

|

|

23 |

DS40A23 |

3,940 |

3.672 |

A |

5/8 |

21/16 |

113/32 |

11/8 |

23/32 |

.284 |

3.5 |

|

|

24 |

DS40A24 |

4.100 |

3.831 |

A |

5/8 |

21/4 |

113/32 |

11/8 |

217/64 |

.284 |

4.0 |

|

Double Single-Taper Bushed-Steel

|

No. Teeth |

Number |

Bushing Size |

De |

Dp |

D1 |

Type |

L1 |

c |

E |

L2 |

B1 |

Wt. Rim Only |

|

|

|

Min |

Max. |

|||||||||||||

|

19 |

DS40ATB19H |

1215 |

3.300 |

3.308 |

1/2 |

1/4 |

A |

113/32 |

11/8 |

21/2 |

11/2 |

.284 |

1.1 |

|

|

20 |

DS40ATB20H |

1215 |

3.460 |

3.196 |

1/2 |

1/4 |

A |

113/32 |

11/8 |

25/8 |

11/2 |

.284 |

1.3 |

|

|

21 |

DS40ATB21H |

1615 |

3.620 |

3.355 |

1/2 |

5/8 |

A |

113/32 |

11/8 |

225/32 |

11/2 |

.284 |

1.3 |

|

|

23 |

DS40ATB23H |

1615 |

3.940 |

3.672 |

1/2 |

5/8 |

A |

113/32 |

11/8 |

23/32 |

11/2 |

.284 |

1.5 |

|

|

24 |

DS40ATB24H |

1615 |

4.100 |

3.831 |

1/2 |

5/8 |

A |

113/32 |

11/8 |

217/64 |

11/2 |

.284 |

1.7 |

|

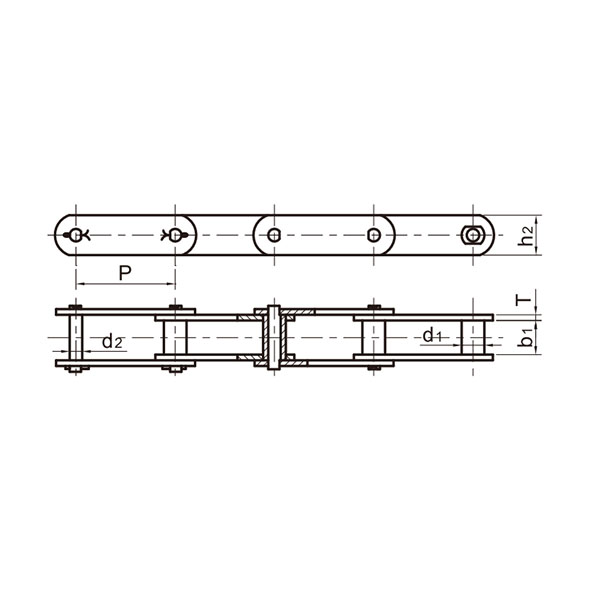

Double single sprockets are designed to run two single-strand type roller chains, this is where the name “double single” came from. Typically these sprockets are A style but both taper bushed and QD style is available produced as custoemrs’ request. Our double single sprockets are manufactured with hardened teeth and have a original colour or black oxide coating for superior performance and a slight corrosion resistance. Stock sizes of double single sprockets range from ANSI #40 – #80/DIN06B-16B but additional sizes can be manufactured upon request. Something important to note is that even though these sprockets are double sprockets they will not double-strand roller chain.

Product detail pictures:

Related Product Guide:

Dedicated to strict high-quality management and considerate shopper company, our experienced team associates are normally available to discuss your requirements and ensure full shopper gratification for New Fashion Design for Conveyor Chain Sprocket - Double Sprockets For Two Single Chains per American Standard – GOODLUCK , The product will supply to all over the world, such as: Jordan, Jamaica, New Delhi, We are committed to meet all your needs and solve any technical problems you may encounter with your industrial components. Our exceptional products and vast knowledge of technology makes us the preferred choice for our customers.

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.