OEM Customized Roller Chain Conveyor - Pintle Chains, type 662, 662H, 667X, 667XH, 667K, 667H, 88K, 88C, 308C – GOODLUCK

OEM Customized Roller Chain Conveyor - Pintle Chains, type 662, 662H, 667X, 667XH, 667K, 667H, 88K, 88C, 308C – GOODLUCK Detail:

|

GL Chain No. |

Pitch mm inch P |

Links per 10FT |

Weight per FT q kg/FT (lb./ FT) |

Ultimate tensile strength Q(min)kN (Lb.) |

Average tensile strength QkN (Lb.) |

Maximum recommend ed working load kN (Lb.) |

Inside width at narrow end b1 mm |

Pin |

Plate |

|||

|

d mm |

L1 mm |

L2 mm |

h mm |

T mm |

||||||||

|

D205 |

31.75 1.25 |

96 |

0.186 0.41 |

18 4,050 |

21.8 4,900 |

2.5 560 |

9.53 0.375 |

5.08 0.2 |

10.7 0.421 |

13.5 0.543 |

11.9 0.469 |

2.1 0.08 |

|

662 |

42.27 1.664 |

72 |

0.506 1.12 |

42.5 9,560 |

49.8 11,200 |

7.6 1,710 |

23.2 0.913 |

7.16 0.282 |

20.75 0.817 |

22.95 0.904 |

18.3 0.72 |

3.20 0.12 |

|

662H |

42.27 1.664 |

72 |

0.622 1.37 |

48.9 11,000 |

52 11,700 |

7.8 1,755 |

23.2 0.913 |

7.16 0.282 |

21.45 0.844 |

23.85 0.939 |

20.4 0.803 |

3.6 0.14 |

|

662HD |

42.27 1.664 |

72 |

0.812 1.79 |

60 13,500 |

65.8 14,800 |

9.3 2,090 |

23.2 0.913 |

7.92 0.312 |

22.75 0.896 |

25.45 1.002 |

22.23 0.87 |

4.3 0.17 |

|

667X |

57.15 2.25 |

53 |

0.887 1.95 |

88.9 20,000 |

96.5 21,700 |

13.4 3,010 |

27 1.063 |

11.1 0.437 |

25 0.984 |

29.3 1.154 |

23.8 0.937 |

4.3 0.17 |

|

667XH |

57.15 2.25 |

53 |

1.314 2.89 |

124.5 28,000 |

138 31,050 |

21.4 4,810 |

27.8 1.094 |

11.91 0.469 |

29.05 1.144 |

32.25 1.27 |

26.8 1.055 |

5.7 0.22 |

|

667K |

57.15 2.25 |

53 |

1.159 2.55 |

106.8 24,000 |

132 19,700 |

17.78 4,000 |

27.8 1.094 |

11.1 0.437 |

27.75 1.093 |

30.85 1.215 |

26.8 1.055 |

5.1 0.20 |

|

667KC |

57.15 2.25 |

53 |

1.16 2.56 |

137.35 30,900 |

148 33,290 |

21.33 4,800 |

27.8 1.094 |

11.1 0.437 |

27.75 1.093 |

30.85 1.215 |

26.8 1.055 |

5.1 0.20 |

|

667H |

58.75 2.313 |

52 |

0.564 1.24 |

52.1 11,720 |

57.4 12,900 |

8.5 1,910 |

25.6 1.008 |

7.92 0.312 |

21.85 0.86 |

24.25 0.955 |

22.23 0.875 |

3.2 0.12 |

|

667J |

57.15 2.313 |

53 |

0.854 1.88 |

86.5 19,460 |

95 21,370 |

13.1 2,950 |

27 1.063 |

9.52 0.375 |

25 0.984 |

29.3 1.154 |

23.8 0.937 |

4.3 0.17 |

|

88K |

66.27 2.609 |

46 |

1.098 2.41 |

106.8 24,000 |

132 29,700 |

17.8 4,000 |

27.8 1.094 |

11.1 0.437 |

27.75 1.093 |

30.85 1.215 |

26.8 1.055 |

5.1 0.20 |

|

88C |

66.27 2.609 |

46 |

1.601 3.53 |

152 34,200 |

169 38,020 |

26.7 6,000 |

31.75 1.25 |

12.7 0.5 |

32.65 1.285 |

35.65 1.404 |

28.58 1.125 |

6.4 0.25 |

|

308C |

78.1 3.075 |

39 |

2.54 5.59 |

200 45,000 |

222 50,000 |

35.6 8,000 |

32.5 1.28 |

15.88 0.625 |

38.25 1.506 |

41.75 1.644 |

38.1 1.5 |

8 0.31 |

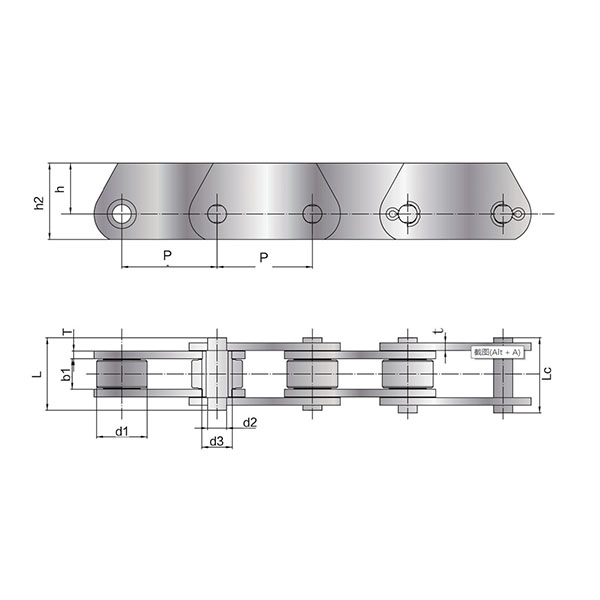

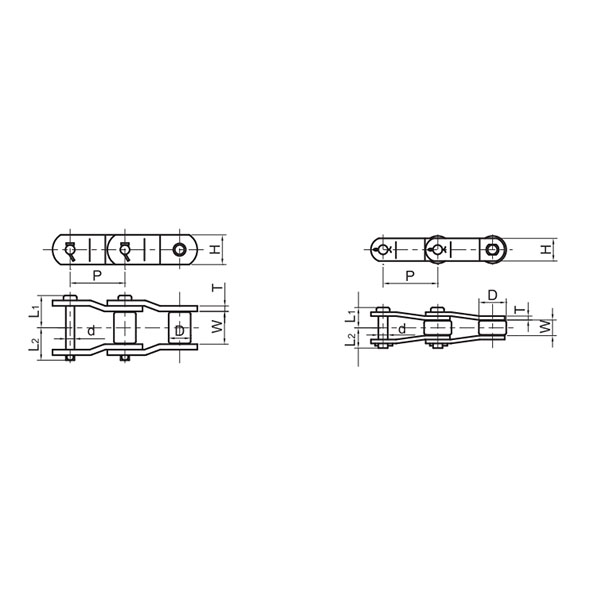

Steel pintle chain is recommended as conveyor chain for a wide range of applications such as spreaders, feeder systems, hay handling equipment and spray box, and in limited use, as power transmission chain. These chains can be applied in the smudgy environment.The main specification includes 662,667H,667X,667HX,667K,667J,88K,88C. And a wide selection of attachments for steel pintle chains are also available to meet specific working purposes.

Product detail pictures:

Related Product Guide:

As a way to provide you advantage and enlarge our organization, we even have inspectors in QC Crew and guarantee you our greatest assistance and product or service for OEM Customized Roller Chain Conveyor - Pintle Chains, type 662, 662H, 667X, 667XH, 667K, 667H, 88K, 88C, 308C – GOODLUCK , The product will supply to all over the world, such as: London, Palestine, India, Our company considers that selling is not only to gain profit but also popularize the culture of our company to the world. So we are working hard to give you the wholehearted service and willing to give you the most competitive price in the market

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.