OEM/ODM China Double Pitch Roller Chain Sprockets - Platewheels per Asian Standard – GOODLUCK

OEM/ODM China Double Pitch Roller Chain Sprockets - Platewheels per Asian Standard – GOODLUCK Detail:

K25A

| SPROCKETS | mm |

| Tooth width (T) | 2.8 |

| CHAIN | mm |

| Pitch (P) | 6.35 |

| Internal width | 3.18 |

| Roller Φ (Dr) | 3.30 |

|

Type |

Teeth |

Do |

Dp |

Bored |

Wt kg |

Material |

|

|

Stock |

Min |

||||||

|

K25A |

10 |

23 |

20.55 |

9 |

11 |

0.02 |

C45 Solid |

|

12 |

28 |

24.53 |

9 |

11 |

0.03 |

||

|

13 |

30 |

26.53 |

9 |

11 |

0.04 |

||

|

14 |

32 |

28.54 |

9 |

11 |

0.04 |

||

|

15 |

34 |

30.54 |

9 |

11 |

0.05 |

||

|

16 |

36 |

32.55 |

9 |

11 |

0.05 |

||

|

17 |

38 |

34.56 |

9 |

11 |

0.07 |

||

|

18 |

40 |

36.57 |

9 |

11 |

0.07 |

||

|

20 |

44 |

40.59 |

9 |

11 |

0.09 |

||

|

24 |

52 |

48.65 |

9 |

11 |

0.14 |

||

|

25 |

54 |

50.66 |

9 |

11 |

0.16 |

||

|

27 |

58 |

54.70 |

9 |

11 |

0.17 |

||

|

28 |

60 |

56.71 |

9 |

11 |

018 |

||

|

29 |

62 |

58.73 |

9 |

11 |

0.20 |

||

|

30 |

64 |

60.75 |

10 |

12 |

0.23 |

||

|

32 |

68 |

64.78 |

10 |

12 |

0.27 |

||

|

33 |

70 |

66.80 |

10 |

12 |

0.28 |

||

|

35 |

74 |

70.84 |

10 |

12 |

0.30 |

||

|

36 |

76 |

72.86 |

10 |

12 |

032 |

||

|

37 |

78 |

74.88 |

10 |

12 |

0.37 |

||

|

38 |

80 |

76.90 |

10 |

12 |

0.41 |

||

|

40 |

84 |

80.93 |

11 |

13 |

0.43 |

||

|

42 |

89 |

84.97 |

11 |

13 |

0.47 |

||

|

45 |

95 |

91.03 |

11 |

13 |

0,50 |

||

|

50 |

105 |

101.13 |

11 |

13 |

0.59 |

||

|

55 |

115 |

111.23 |

11 |

13 |

0.70 |

||

|

60 |

125 |

121.33 |

11 |

13 |

0.87 |

||

|

70 |

145 |

141.54 |

11 |

13 |

1.81 |

||

|

75 |

155 |

151.64 |

12 |

14 |

1.37 |

||

|

80 |

165 |

161.74 |

12 |

14 |

1.62 |

||

K25A

| SPROCKETS | mm |

| Tooth width (T) | 4.3 |

| CHAIN | mm |

| Pitch (P) | 9.25 |

| Internal width | 4.78 |

| Roller Φ (Dr) | 5.08 |

|

Type |

Teeth |

Do |

Dp |

Bored |

wt kg |

Material |

|

|

Stock |

Min |

||||||

|

K35A |

10 |

34 |

30.82 |

9 |

11 |

0.02 |

C45 Solid |

|

11 |

38 |

33.81 |

9 |

11 |

0.03 |

||

|

12 |

41 |

36.80 |

9 |

11 |

0.03 |

||

|

13 |

44 |

39.80 |

9 |

11 |

0.04 |

||

|

14 |

47 |

42.81 |

9 |

11 |

0.04 |

||

|

15 |

51 |

45.81 |

9 |

11 |

0.05 |

||

|

16 |

54 |

48.82 |

9 |

11 |

0.05 |

||

|

17 |

57 |

51.84 |

11 |

13 |

0.07 |

||

|

18 |

60 |

54.85 |

11 |

13 |

0.07 |

||

|

19 |

63 |

57.87 |

11 |

13 |

0.09 |

||

|

20 |

66 |

60.89 |

11 |

13 |

0.09 |

||

|

21 |

69 |

63.91 |

11 |

13 |

0.11 |

||

|

22 |

72 |

66.93 |

11 |

13 |

0.11 |

||

|

23 |

75 |

69,95 |

11 |

13 |

0.11 |

||

|

24 |

78 |

72.97 |

11 |

13 |

0.14 |

||

|

25 |

81 |

76.00 |

11 |

13 |

0.16 |

||

|

26 |

84 |

79.02 |

11 |

13 |

0.16 |

||

|

27 |

87 |

82,05 |

11 |

13 |

0.17 |

||

|

28 |

90 |

85.07 |

11 |

13 |

0.18 |

||

|

30 |

96 |

9142 |

11 |

13 |

0.23 |

||

|

32 |

102 |

97.18 |

11 |

13 |

0.27 |

||

|

33 |

105 |

100.20 |

11 |

13 |

0.28 |

||

|

34 |

109 |

103.23 |

11 |

13 |

0.29 |

||

|

35 |

112 |

106.26 |

11 |

13 |

0.30 |

||

|

36 |

115 |

109.29 |

12 |

14 |

0.32 |

||

|

38 |

121 |

115.34 |

12 |

14 |

0.37 |

||

|

40 |

127 |

121.40 |

12 |

14 |

0.40 |

||

|

42 |

133 |

127.46 |

16 |

18 |

0.43 |

||

|

45 |

142 |

136.55 |

16 |

18 |

0.49 |

||

|

46 |

145 |

139.58 |

16 |

18 |

0.51 |

||

|

4S |

151 |

145.64 |

16 |

18 |

0.55 |

||

|

50 |

157 |

151.70 |

16 |

18 |

0.60 |

||

|

54 |

169 |

163.81 |

16 |

18 |

0.70 |

||

|

55 |

172 |

166.85 |

16 |

18 |

0.71 |

||

|

60 |

187 |

182.00 |

16 |

18 |

0.80 |

||

|

65 |

203 |

197.15 |

16 |

18 |

1.02 |

||

|

70 |

218 |

212,30 |

16 |

18 |

1.18 |

||

|

80 |

24B |

242.60 |

16 |

18 |

1.50 |

||

K410A

| SPROCKETS | mm |

| Tooth width (T) | 2.8 |

| CHAIN | mm |

| Pitch (P) | 12.70 |

| Internal width | 3.4 |

| Roller Φ (Dr) | 7.75 |

|

Type |

Teeth |

Do |

Dp |

Bored |

Wt kg |

Material |

|

|

Stock |

Min |

||||||

| K410A |

8 |

38 |

33.19 |

10 |

12 |

0.01 |

C45 Solid |

|

9 |

42 |

37.13 |

10 |

12 |

0.02 |

||

|

10 |

46 |

41.10 |

11 |

13 |

0.05 |

||

|

11 |

51 |

45.08 |

12 |

14 |

0.09 |

||

|

12 |

55 |

49.07 |

12 |

14 |

0.10 |

||

|

13 |

59 |

53.07 |

15 |

17 |

0,12 |

||

|

14 |

63 |

57.07 |

15 |

17 |

0.14 |

||

|

IS |

67 |

61.08 |

15 |

17 |

0.16 |

||

|

16 |

71 |

65.10 |

15 |

17 |

0.18 |

||

|

17 |

76 |

69.12 |

15 |

17 |

0.20 |

||

|

18 |

80 |

73.14 |

15 |

17 |

0.23 |

||

|

19 |

84 |

77.16 |

15 |

17 |

0.26 |

||

|

20 |

88 |

81.18 |

16 |

18 |

0.29 |

||

|

21 |

92 |

85.21 |

16 |

18 |

0.30 |

||

|

22 |

96 |

89.24 |

16 |

18 |

0.35 |

||

|

23 |

100 |

93.27 |

16 |

18 |

0.38 |

||

|

24 |

104 |

9730 |

16 |

18 |

0.40 |

||

|

25 |

108 |

101.33 |

16 |

18 |

0.45 |

||

|

26 |

112 |

105.36 |

16 |

18 |

0.49 |

||

|

27 |

116 |

109.40 |

16 |

18 |

0.50 |

||

|

28 |

120 |

113.43 |

16 |

18 |

0.56 |

||

|

29 |

124 |

117.46 |

16 |

18 |

0.60 |

||

|

30 |

128 |

12L50 |

16 |

18 |

0.63 |

||

|

31 |

133 |

125.53 |

16 |

18 |

0.65 |

||

|

32 |

137 |

129.57 |

16 |

18 |

0.70 |

||

|

33 |

141 |

133.61 |

16 |

18 |

0.75 |

||

|

34 |

145 |

137.64 |

16 |

18 |

0.80 |

||

|

35 |

149 |

141.68 |

16 |

18 |

0.85 |

||

|

36 |

153 |

145.72 |

18 |

20 |

0.90 |

||

|

37 |

157 |

149.75 |

18 |

20 |

0.99 |

||

|

38 |

161 |

153.79 |

18 |

20 |

1.00 |

||

|

39 |

165 |

157.83 |

18 |

20 |

1.18 |

||

|

40 |

169 |

161.87 |

18 |

20 |

1.20 |

||

|

41 |

173 |

165.91 |

18 |

20 |

1.20 |

||

|

42 |

177 |

169.94 |

18 |

20 |

1.25 |

||

|

44 |

185 |

178.02 |

18 |

20 |

135 |

||

|

45 |

189 |

182.06 |

18 |

20 |

1.40 |

||

|

46 |

193 |

186.10 |

18 |

20 |

1.49 |

||

|

47 |

197 |

190.14 |

18 |

20 |

1.58 |

||

|

48 |

201 |

194.18 |

18 |

20 |

1.63 |

||

|

49 |

205 |

198.22 |

18 |

20 |

1.73 |

||

|

50 |

209 |

202.26 |

18 |

20 |

1.80 |

||

|

52 |

218 |

210.34 |

18 |

20 |

1.93 |

||

|

54 |

226 |

Z18-42 |

18 |

20 |

2.00 |

||

|

60 |

250 |

242.66 |

18 |

20 |

2.60 |

||

K40A

| SPROCKETS | mm |

| Tooth width (T) | 7.2 |

| CHAIN | mm |

| Pitch (P) | 12.7 |

| Internal width | 7.95 |

| Roller Φ (Dr) | 7.95 |

|

Type |

Teeth |

Do |

Dp |

Bored Stock |

Min |

Wt kg |

Material |

|

K4OA |

10 |

46 |

41.10 |

9.5 |

115 |

0.05 |

C45 Solid |

|

11 |

51 |

45.08 |

10.5 |

12.5 |

0.09 |

||

|

12 |

55 |

49.07 |

11.5 |

13.5 |

0.10 |

||

|

13 |

59 |

53.07 |

13.5 |

15-5 |

0.12 |

||

|

14 |

63 |

57.07 |

13.5 |

15.5 |

0.14 |

||

|

15 |

67 |

61.08 |

13.5 |

15.5 |

0J6 |

||

|

16 |

71 |

65.10 |

13.5 |

15.5 |

0.18 |

||

|

17 |

76 |

69.12 |

13.5 |

15,5 |

0.20 |

||

|

18 |

80 |

73.14 |

13-5 |

15,5 |

0.23 |

||

|

19 |

84 |

77.16 |

13.5 |

15.5 |

0.26 |

||

|

20 |

88 |

81.18 |

14 |

16 |

0.29 |

||

|

21 |

92 |

85.21 |

14 |

16 |

0.30 |

||

|

22 |

96 |

89.24 |

14 |

16 |

0.35 |

||

|

23 |

100 |

93.27 |

14 |

16 |

0.38 |

||

|

24 |

104 |

97.30 |

14 |

16 |

0.40 |

||

|

25 |

108 |

101.33 |

14 |

16 |

0.45 |

||

|

26 |

112 |

105.36 |

14 |

16 |

0.49 |

||

|

27 |

116 |

109.40 |

14 |

16 |

0.50 |

||

|

28 |

120 |

113.43 |

14 |

16 |

0.56 |

||

|

29 |

124 |

117.46 |

14 |

16 |

0.60 |

||

|

30 |

128 |

121.50 |

14 |

16 |

0.63 |

||

|

31 |

133 |

125.53 |

14 |

16 |

0.65 |

||

|

32 |

137 |

129.57 |

14 |

16 |

0.70 |

||

|

33 |

141 |

133.61 |

14 |

16 |

0.75 |

||

|

34 |

145 |

137.64 |

14 |

16 |

0-80 |

||

|

35 |

149 |

141,68 |

14 |

16 |

0.85 |

||

|

36 |

153 |

145.72 |

16 |

18 |

0.90 |

||

|

37 |

157 |

149.75 |

16 |

18 |

0.99 |

||

|

38 |

161 |

153.79 |

16 |

18 |

1.00 |

||

|

39 |

165 |

157.83 |

16 |

18 |

1.15 |

||

|

40 |

169 |

161.87 |

16 |

18 |

1.20 |

||

|

41 |

173 |

165.91 |

16 |

18 |

1.20 |

||

|

42 |

177 |

169.95 |

16 |

18 |

1.25 |

||

|

43 |

181 |

173.98 |

16 |

18 |

1.30 |

||

|

44 |

185 |

178.02 |

16 |

18 |

1.35 |

||

|

45 |

189 |

182.06 |

16 |

18 |

1.40 |

||

|

46 |

193 |

186.10 |

16 |

18 |

1.49 |

||

|

47 |

197 |

190.14 |

16 |

18 |

1.58 |

||

| 48 |

201 |

194.18 |

16 |

18 |

1-63 |

||

|

49 |

205 |

198.22 |

16 |

18 |

1.73 |

||

|

50 |

209 |

202.26 |

16 |

18 |

1.80 |

||

|

51 |

214 |

206.30 |

16 |

18 |

1.88 |

||

|

52 |

218 |

210.34 |

16 |

18 |

1.93 |

||

|

53 |

222 |

214.38 |

16 |

18 |

1.98 |

||

|

54 |

226 |

218.42 |

16 |

18 |

2.00 |

||

|

S5 |

230 |

222.46 |

16 |

18 |

2.18 |

||

|

56 |

234 |

226.50 |

16 |

18 |

2.26 |

||

|

58 |

242 |

234.58 |

16 |

18 |

2.43 |

||

|

59 |

246 |

238.62 |

16 |

18 |

2.51 |

||

|

60 |

250 |

242,66 |

16 |

18 |

2.60 |

||

|

62 |

258 |

250.74 |

16 |

18 |

2.77 |

||

|

64 |

266 |

258.83 |

16 |

18 |

2.90 |

||

|

65 |

270 |

262.87 |

16 |

18 |

3.00 |

||

|

68 |

282 |

274.99 |

16 |

18 |

3.35 |

||

|

70 |

290 |

283.07 |

16 |

18 |

3.50 |

||

|

72 |

299 |

291.16 |

20 |

22 |

370 |

||

|

75 |

311 |

303,28 |

20 |

22 |

4.00 |

||

|

80 |

331 |

323.49 |

20 |

22 |

4.60 |

||

|

85 |

351 |

343.69 |

20 |

22 |

5.20 |

||

|

90 |

371 |

363.90 |

20 |

22 |

5.80 |

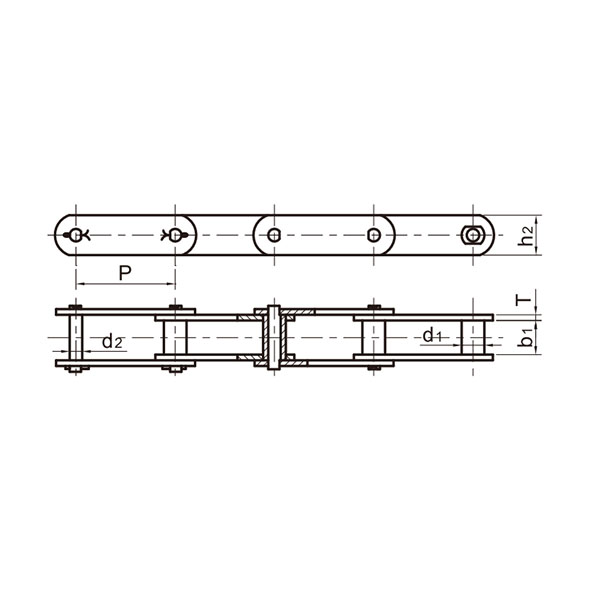

Plate wheel:

The plate wheel helps to determine the performance and service life of the chain

Plate wheels help determine the performance and service life of the chain, so GL provides appropriate corresponding plate wheels from its extensive inventory of all chains. This ensures proper alignment between the chain and the plate wheels and prevents fit differences that can affect the overall life of the chain drive. GL also manufactures the sprockets and plate wheels from solid materials or welded material exactly as the customer requires. GL offers a variety of tooth shapes and material options with or without hardened teeth. Designs include simplex, duplex, triplex and cast iron. European standard / AMERICA standard / Asian standard are avilable.

Product detail pictures:

Related Product Guide:

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for OEM/ODM China Double Pitch Roller Chain Sprockets - Platewheels per Asian Standard – GOODLUCK , The product will supply to all over the world, such as: Panama, Plymouth, Chile, we have all day online sales to make sure the pre-sale and after-sale service in time. With all these supports, we can serve every customer with quality product and timely shipping with highly responsibility. Being a young growing company, we might not the best, but we are trying our best to be your good partner.

The sales manager has a good English level and skilled professional knowledge, we have a good communication. He is a warm and cheerful man, we have a pleasant cooperation and we became very good friends in private.