OEM/ODM China Double Pitch Roller Chain Sprockets - Platewheels per Asian Standard – GOODLUCK

OEM/ODM China Double Pitch Roller Chain Sprockets - Platewheels per Asian Standard – GOODLUCK Detail:

K25A

| SPROCKETS | mm |

| Tooth width (T) | 2.8 |

| CHAIN | mm |

| Pitch (P) | 6.35 |

| Internal width | 3.18 |

| Roller Φ (Dr) | 3.30 |

|

Type |

Teeth |

Do |

Dp |

Bored |

Wt kg |

Material |

|

|

Stock |

Min |

||||||

|

K25A |

10 |

23 |

20.55 |

9 |

11 |

0.02 |

C45 Solid |

|

12 |

28 |

24.53 |

9 |

11 |

0.03 |

||

|

13 |

30 |

26.53 |

9 |

11 |

0.04 |

||

|

14 |

32 |

28.54 |

9 |

11 |

0.04 |

||

|

15 |

34 |

30.54 |

9 |

11 |

0.05 |

||

|

16 |

36 |

32.55 |

9 |

11 |

0.05 |

||

|

17 |

38 |

34.56 |

9 |

11 |

0.07 |

||

|

18 |

40 |

36.57 |

9 |

11 |

0.07 |

||

|

20 |

44 |

40.59 |

9 |

11 |

0.09 |

||

|

24 |

52 |

48.65 |

9 |

11 |

0.14 |

||

|

25 |

54 |

50.66 |

9 |

11 |

0.16 |

||

|

27 |

58 |

54.70 |

9 |

11 |

0.17 |

||

|

28 |

60 |

56.71 |

9 |

11 |

018 |

||

|

29 |

62 |

58.73 |

9 |

11 |

0.20 |

||

|

30 |

64 |

60.75 |

10 |

12 |

0.23 |

||

|

32 |

68 |

64.78 |

10 |

12 |

0.27 |

||

|

33 |

70 |

66.80 |

10 |

12 |

0.28 |

||

|

35 |

74 |

70.84 |

10 |

12 |

0.30 |

||

|

36 |

76 |

72.86 |

10 |

12 |

032 |

||

|

37 |

78 |

74.88 |

10 |

12 |

0.37 |

||

|

38 |

80 |

76.90 |

10 |

12 |

0.41 |

||

|

40 |

84 |

80.93 |

11 |

13 |

0.43 |

||

|

42 |

89 |

84.97 |

11 |

13 |

0.47 |

||

|

45 |

95 |

91.03 |

11 |

13 |

0,50 |

||

|

50 |

105 |

101.13 |

11 |

13 |

0.59 |

||

|

55 |

115 |

111.23 |

11 |

13 |

0.70 |

||

|

60 |

125 |

121.33 |

11 |

13 |

0.87 |

||

|

70 |

145 |

141.54 |

11 |

13 |

1.81 |

||

|

75 |

155 |

151.64 |

12 |

14 |

1.37 |

||

|

80 |

165 |

161.74 |

12 |

14 |

1.62 |

||

K25A

| SPROCKETS | mm |

| Tooth width (T) | 4.3 |

| CHAIN | mm |

| Pitch (P) | 9.25 |

| Internal width | 4.78 |

| Roller Φ (Dr) | 5.08 |

|

Type |

Teeth |

Do |

Dp |

Bored |

wt kg |

Material |

|

|

Stock |

Min |

||||||

|

K35A |

10 |

34 |

30.82 |

9 |

11 |

0.02 |

C45 Solid |

|

11 |

38 |

33.81 |

9 |

11 |

0.03 |

||

|

12 |

41 |

36.80 |

9 |

11 |

0.03 |

||

|

13 |

44 |

39.80 |

9 |

11 |

0.04 |

||

|

14 |

47 |

42.81 |

9 |

11 |

0.04 |

||

|

15 |

51 |

45.81 |

9 |

11 |

0.05 |

||

|

16 |

54 |

48.82 |

9 |

11 |

0.05 |

||

|

17 |

57 |

51.84 |

11 |

13 |

0.07 |

||

|

18 |

60 |

54.85 |

11 |

13 |

0.07 |

||

|

19 |

63 |

57.87 |

11 |

13 |

0.09 |

||

|

20 |

66 |

60.89 |

11 |

13 |

0.09 |

||

|

21 |

69 |

63.91 |

11 |

13 |

0.11 |

||

|

22 |

72 |

66.93 |

11 |

13 |

0.11 |

||

|

23 |

75 |

69,95 |

11 |

13 |

0.11 |

||

|

24 |

78 |

72.97 |

11 |

13 |

0.14 |

||

|

25 |

81 |

76.00 |

11 |

13 |

0.16 |

||

|

26 |

84 |

79.02 |

11 |

13 |

0.16 |

||

|

27 |

87 |

82,05 |

11 |

13 |

0.17 |

||

|

28 |

90 |

85.07 |

11 |

13 |

0.18 |

||

|

30 |

96 |

9142 |

11 |

13 |

0.23 |

||

|

32 |

102 |

97.18 |

11 |

13 |

0.27 |

||

|

33 |

105 |

100.20 |

11 |

13 |

0.28 |

||

|

34 |

109 |

103.23 |

11 |

13 |

0.29 |

||

|

35 |

112 |

106.26 |

11 |

13 |

0.30 |

||

|

36 |

115 |

109.29 |

12 |

14 |

0.32 |

||

|

38 |

121 |

115.34 |

12 |

14 |

0.37 |

||

|

40 |

127 |

121.40 |

12 |

14 |

0.40 |

||

|

42 |

133 |

127.46 |

16 |

18 |

0.43 |

||

|

45 |

142 |

136.55 |

16 |

18 |

0.49 |

||

|

46 |

145 |

139.58 |

16 |

18 |

0.51 |

||

|

4S |

151 |

145.64 |

16 |

18 |

0.55 |

||

|

50 |

157 |

151.70 |

16 |

18 |

0.60 |

||

|

54 |

169 |

163.81 |

16 |

18 |

0.70 |

||

|

55 |

172 |

166.85 |

16 |

18 |

0.71 |

||

|

60 |

187 |

182.00 |

16 |

18 |

0.80 |

||

|

65 |

203 |

197.15 |

16 |

18 |

1.02 |

||

|

70 |

218 |

212,30 |

16 |

18 |

1.18 |

||

|

80 |

24B |

242.60 |

16 |

18 |

1.50 |

||

K410A

| SPROCKETS | mm |

| Tooth width (T) | 2.8 |

| CHAIN | mm |

| Pitch (P) | 12.70 |

| Internal width | 3.4 |

| Roller Φ (Dr) | 7.75 |

|

Type |

Teeth |

Do |

Dp |

Bored |

Wt kg |

Material |

|

|

Stock |

Min |

||||||

| K410A |

8 |

38 |

33.19 |

10 |

12 |

0.01 |

C45 Solid |

|

9 |

42 |

37.13 |

10 |

12 |

0.02 |

||

|

10 |

46 |

41.10 |

11 |

13 |

0.05 |

||

|

11 |

51 |

45.08 |

12 |

14 |

0.09 |

||

|

12 |

55 |

49.07 |

12 |

14 |

0.10 |

||

|

13 |

59 |

53.07 |

15 |

17 |

0,12 |

||

|

14 |

63 |

57.07 |

15 |

17 |

0.14 |

||

|

IS |

67 |

61.08 |

15 |

17 |

0.16 |

||

|

16 |

71 |

65.10 |

15 |

17 |

0.18 |

||

|

17 |

76 |

69.12 |

15 |

17 |

0.20 |

||

|

18 |

80 |

73.14 |

15 |

17 |

0.23 |

||

|

19 |

84 |

77.16 |

15 |

17 |

0.26 |

||

|

20 |

88 |

81.18 |

16 |

18 |

0.29 |

||

|

21 |

92 |

85.21 |

16 |

18 |

0.30 |

||

|

22 |

96 |

89.24 |

16 |

18 |

0.35 |

||

|

23 |

100 |

93.27 |

16 |

18 |

0.38 |

||

|

24 |

104 |

9730 |

16 |

18 |

0.40 |

||

|

25 |

108 |

101.33 |

16 |

18 |

0.45 |

||

|

26 |

112 |

105.36 |

16 |

18 |

0.49 |

||

|

27 |

116 |

109.40 |

16 |

18 |

0.50 |

||

|

28 |

120 |

113.43 |

16 |

18 |

0.56 |

||

|

29 |

124 |

117.46 |

16 |

18 |

0.60 |

||

|

30 |

128 |

12L50 |

16 |

18 |

0.63 |

||

|

31 |

133 |

125.53 |

16 |

18 |

0.65 |

||

|

32 |

137 |

129.57 |

16 |

18 |

0.70 |

||

|

33 |

141 |

133.61 |

16 |

18 |

0.75 |

||

|

34 |

145 |

137.64 |

16 |

18 |

0.80 |

||

|

35 |

149 |

141.68 |

16 |

18 |

0.85 |

||

|

36 |

153 |

145.72 |

18 |

20 |

0.90 |

||

|

37 |

157 |

149.75 |

18 |

20 |

0.99 |

||

|

38 |

161 |

153.79 |

18 |

20 |

1.00 |

||

|

39 |

165 |

157.83 |

18 |

20 |

1.18 |

||

|

40 |

169 |

161.87 |

18 |

20 |

1.20 |

||

|

41 |

173 |

165.91 |

18 |

20 |

1.20 |

||

|

42 |

177 |

169.94 |

18 |

20 |

1.25 |

||

|

44 |

185 |

178.02 |

18 |

20 |

135 |

||

|

45 |

189 |

182.06 |

18 |

20 |

1.40 |

||

|

46 |

193 |

186.10 |

18 |

20 |

1.49 |

||

|

47 |

197 |

190.14 |

18 |

20 |

1.58 |

||

|

48 |

201 |

194.18 |

18 |

20 |

1.63 |

||

|

49 |

205 |

198.22 |

18 |

20 |

1.73 |

||

|

50 |

209 |

202.26 |

18 |

20 |

1.80 |

||

|

52 |

218 |

210.34 |

18 |

20 |

1.93 |

||

|

54 |

226 |

Z18-42 |

18 |

20 |

2.00 |

||

|

60 |

250 |

242.66 |

18 |

20 |

2.60 |

||

K40A

| SPROCKETS | mm |

| Tooth width (T) | 7.2 |

| CHAIN | mm |

| Pitch (P) | 12.7 |

| Internal width | 7.95 |

| Roller Φ (Dr) | 7.95 |

|

Type |

Teeth |

Do |

Dp |

Bored Stock |

Min |

Wt kg |

Material |

|

K4OA |

10 |

46 |

41.10 |

9.5 |

115 |

0.05 |

C45 Solid |

|

11 |

51 |

45.08 |

10.5 |

12.5 |

0.09 |

||

|

12 |

55 |

49.07 |

11.5 |

13.5 |

0.10 |

||

|

13 |

59 |

53.07 |

13.5 |

15-5 |

0.12 |

||

|

14 |

63 |

57.07 |

13.5 |

15.5 |

0.14 |

||

|

15 |

67 |

61.08 |

13.5 |

15.5 |

0J6 |

||

|

16 |

71 |

65.10 |

13.5 |

15.5 |

0.18 |

||

|

17 |

76 |

69.12 |

13.5 |

15,5 |

0.20 |

||

|

18 |

80 |

73.14 |

13-5 |

15,5 |

0.23 |

||

|

19 |

84 |

77.16 |

13.5 |

15.5 |

0.26 |

||

|

20 |

88 |

81.18 |

14 |

16 |

0.29 |

||

|

21 |

92 |

85.21 |

14 |

16 |

0.30 |

||

|

22 |

96 |

89.24 |

14 |

16 |

0.35 |

||

|

23 |

100 |

93.27 |

14 |

16 |

0.38 |

||

|

24 |

104 |

97.30 |

14 |

16 |

0.40 |

||

|

25 |

108 |

101.33 |

14 |

16 |

0.45 |

||

|

26 |

112 |

105.36 |

14 |

16 |

0.49 |

||

|

27 |

116 |

109.40 |

14 |

16 |

0.50 |

||

|

28 |

120 |

113.43 |

14 |

16 |

0.56 |

||

|

29 |

124 |

117.46 |

14 |

16 |

0.60 |

||

|

30 |

128 |

121.50 |

14 |

16 |

0.63 |

||

|

31 |

133 |

125.53 |

14 |

16 |

0.65 |

||

|

32 |

137 |

129.57 |

14 |

16 |

0.70 |

||

|

33 |

141 |

133.61 |

14 |

16 |

0.75 |

||

|

34 |

145 |

137.64 |

14 |

16 |

0-80 |

||

|

35 |

149 |

141,68 |

14 |

16 |

0.85 |

||

|

36 |

153 |

145.72 |

16 |

18 |

0.90 |

||

|

37 |

157 |

149.75 |

16 |

18 |

0.99 |

||

|

38 |

161 |

153.79 |

16 |

18 |

1.00 |

||

|

39 |

165 |

157.83 |

16 |

18 |

1.15 |

||

|

40 |

169 |

161.87 |

16 |

18 |

1.20 |

||

|

41 |

173 |

165.91 |

16 |

18 |

1.20 |

||

|

42 |

177 |

169.95 |

16 |

18 |

1.25 |

||

|

43 |

181 |

173.98 |

16 |

18 |

1.30 |

||

|

44 |

185 |

178.02 |

16 |

18 |

1.35 |

||

|

45 |

189 |

182.06 |

16 |

18 |

1.40 |

||

|

46 |

193 |

186.10 |

16 |

18 |

1.49 |

||

|

47 |

197 |

190.14 |

16 |

18 |

1.58 |

||

| 48 |

201 |

194.18 |

16 |

18 |

1-63 |

||

|

49 |

205 |

198.22 |

16 |

18 |

1.73 |

||

|

50 |

209 |

202.26 |

16 |

18 |

1.80 |

||

|

51 |

214 |

206.30 |

16 |

18 |

1.88 |

||

|

52 |

218 |

210.34 |

16 |

18 |

1.93 |

||

|

53 |

222 |

214.38 |

16 |

18 |

1.98 |

||

|

54 |

226 |

218.42 |

16 |

18 |

2.00 |

||

|

S5 |

230 |

222.46 |

16 |

18 |

2.18 |

||

|

56 |

234 |

226.50 |

16 |

18 |

2.26 |

||

|

58 |

242 |

234.58 |

16 |

18 |

2.43 |

||

|

59 |

246 |

238.62 |

16 |

18 |

2.51 |

||

|

60 |

250 |

242,66 |

16 |

18 |

2.60 |

||

|

62 |

258 |

250.74 |

16 |

18 |

2.77 |

||

|

64 |

266 |

258.83 |

16 |

18 |

2.90 |

||

|

65 |

270 |

262.87 |

16 |

18 |

3.00 |

||

|

68 |

282 |

274.99 |

16 |

18 |

3.35 |

||

|

70 |

290 |

283.07 |

16 |

18 |

3.50 |

||

|

72 |

299 |

291.16 |

20 |

22 |

370 |

||

|

75 |

311 |

303,28 |

20 |

22 |

4.00 |

||

|

80 |

331 |

323.49 |

20 |

22 |

4.60 |

||

|

85 |

351 |

343.69 |

20 |

22 |

5.20 |

||

|

90 |

371 |

363.90 |

20 |

22 |

5.80 |

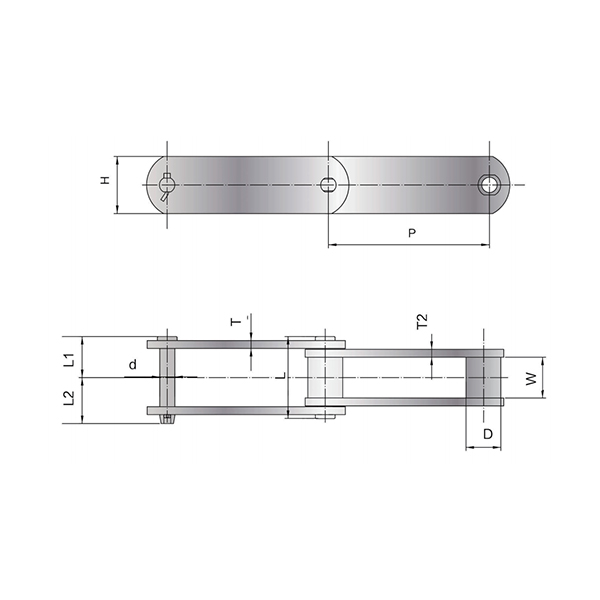

Plate wheel:

The plate wheel helps to determine the performance and service life of the chain

Plate wheels help determine the performance and service life of the chain, so GL provides appropriate corresponding plate wheels from its extensive inventory of all chains. This ensures proper alignment between the chain and the plate wheels and prevents fit differences that can affect the overall life of the chain drive. GL also manufactures the sprockets and plate wheels from solid materials or welded material exactly as the customer requires. GL offers a variety of tooth shapes and material options with or without hardened teeth. Designs include simplex, duplex, triplex and cast iron. European standard / AMERICA standard / Asian standard are avilable.

Product detail pictures:

Related Product Guide:

Fast and very good quotations, informed advisers to help you choose the correct merchandise that suits all your preferences, a short creation time, responsible excellent command and different companies for paying and shipping affairs for OEM/ODM China Double Pitch Roller Chain Sprockets - Platewheels per Asian Standard – GOODLUCK , The product will supply to all over the world, such as: Serbia, Brasilia, Swedish, Faced with the vitality of the global wave of economic integration, we've been confident with our high-quality items and sincerely service to all our customers and wish we can cooperate with you to create a brilliant future.

This company conforms to the market requirement and joins in the market competition by its high quality product, this is an enterprise that have Chinese spirit.