Professional China Cast Iron Sprockets - Platewheels per Asian Standard – GOODLUCK

Professional China Cast Iron Sprockets - Platewheels per Asian Standard – GOODLUCK Detail:

K25A

| SPROCKETS | mm |

| Tooth width (T) | 2.8 |

| CHAIN | mm |

| Pitch (P) | 6.35 |

| Internal width | 3.18 |

| Roller Φ (Dr) | 3.30 |

|

Type |

Teeth |

Do |

Dp |

Bored |

Wt kg |

Material |

|

|

Stock |

Min |

||||||

|

K25A |

10 |

23 |

20.55 |

9 |

11 |

0.02 |

C45 Solid |

|

12 |

28 |

24.53 |

9 |

11 |

0.03 |

||

|

13 |

30 |

26.53 |

9 |

11 |

0.04 |

||

|

14 |

32 |

28.54 |

9 |

11 |

0.04 |

||

|

15 |

34 |

30.54 |

9 |

11 |

0.05 |

||

|

16 |

36 |

32.55 |

9 |

11 |

0.05 |

||

|

17 |

38 |

34.56 |

9 |

11 |

0.07 |

||

|

18 |

40 |

36.57 |

9 |

11 |

0.07 |

||

|

20 |

44 |

40.59 |

9 |

11 |

0.09 |

||

|

24 |

52 |

48.65 |

9 |

11 |

0.14 |

||

|

25 |

54 |

50.66 |

9 |

11 |

0.16 |

||

|

27 |

58 |

54.70 |

9 |

11 |

0.17 |

||

|

28 |

60 |

56.71 |

9 |

11 |

018 |

||

|

29 |

62 |

58.73 |

9 |

11 |

0.20 |

||

|

30 |

64 |

60.75 |

10 |

12 |

0.23 |

||

|

32 |

68 |

64.78 |

10 |

12 |

0.27 |

||

|

33 |

70 |

66.80 |

10 |

12 |

0.28 |

||

|

35 |

74 |

70.84 |

10 |

12 |

0.30 |

||

|

36 |

76 |

72.86 |

10 |

12 |

032 |

||

|

37 |

78 |

74.88 |

10 |

12 |

0.37 |

||

|

38 |

80 |

76.90 |

10 |

12 |

0.41 |

||

|

40 |

84 |

80.93 |

11 |

13 |

0.43 |

||

|

42 |

89 |

84.97 |

11 |

13 |

0.47 |

||

|

45 |

95 |

91.03 |

11 |

13 |

0,50 |

||

|

50 |

105 |

101.13 |

11 |

13 |

0.59 |

||

|

55 |

115 |

111.23 |

11 |

13 |

0.70 |

||

|

60 |

125 |

121.33 |

11 |

13 |

0.87 |

||

|

70 |

145 |

141.54 |

11 |

13 |

1.81 |

||

|

75 |

155 |

151.64 |

12 |

14 |

1.37 |

||

|

80 |

165 |

161.74 |

12 |

14 |

1.62 |

||

K25A

| SPROCKETS | mm |

| Tooth width (T) | 4.3 |

| CHAIN | mm |

| Pitch (P) | 9.25 |

| Internal width | 4.78 |

| Roller Φ (Dr) | 5.08 |

|

Type |

Teeth |

Do |

Dp |

Bored |

wt kg |

Material |

|

|

Stock |

Min |

||||||

|

K35A |

10 |

34 |

30.82 |

9 |

11 |

0.02 |

C45 Solid |

|

11 |

38 |

33.81 |

9 |

11 |

0.03 |

||

|

12 |

41 |

36.80 |

9 |

11 |

0.03 |

||

|

13 |

44 |

39.80 |

9 |

11 |

0.04 |

||

|

14 |

47 |

42.81 |

9 |

11 |

0.04 |

||

|

15 |

51 |

45.81 |

9 |

11 |

0.05 |

||

|

16 |

54 |

48.82 |

9 |

11 |

0.05 |

||

|

17 |

57 |

51.84 |

11 |

13 |

0.07 |

||

|

18 |

60 |

54.85 |

11 |

13 |

0.07 |

||

|

19 |

63 |

57.87 |

11 |

13 |

0.09 |

||

|

20 |

66 |

60.89 |

11 |

13 |

0.09 |

||

|

21 |

69 |

63.91 |

11 |

13 |

0.11 |

||

|

22 |

72 |

66.93 |

11 |

13 |

0.11 |

||

|

23 |

75 |

69,95 |

11 |

13 |

0.11 |

||

|

24 |

78 |

72.97 |

11 |

13 |

0.14 |

||

|

25 |

81 |

76.00 |

11 |

13 |

0.16 |

||

|

26 |

84 |

79.02 |

11 |

13 |

0.16 |

||

|

27 |

87 |

82,05 |

11 |

13 |

0.17 |

||

|

28 |

90 |

85.07 |

11 |

13 |

0.18 |

||

|

30 |

96 |

9142 |

11 |

13 |

0.23 |

||

|

32 |

102 |

97.18 |

11 |

13 |

0.27 |

||

|

33 |

105 |

100.20 |

11 |

13 |

0.28 |

||

|

34 |

109 |

103.23 |

11 |

13 |

0.29 |

||

|

35 |

112 |

106.26 |

11 |

13 |

0.30 |

||

|

36 |

115 |

109.29 |

12 |

14 |

0.32 |

||

|

38 |

121 |

115.34 |

12 |

14 |

0.37 |

||

|

40 |

127 |

121.40 |

12 |

14 |

0.40 |

||

|

42 |

133 |

127.46 |

16 |

18 |

0.43 |

||

|

45 |

142 |

136.55 |

16 |

18 |

0.49 |

||

|

46 |

145 |

139.58 |

16 |

18 |

0.51 |

||

|

4S |

151 |

145.64 |

16 |

18 |

0.55 |

||

|

50 |

157 |

151.70 |

16 |

18 |

0.60 |

||

|

54 |

169 |

163.81 |

16 |

18 |

0.70 |

||

|

55 |

172 |

166.85 |

16 |

18 |

0.71 |

||

|

60 |

187 |

182.00 |

16 |

18 |

0.80 |

||

|

65 |

203 |

197.15 |

16 |

18 |

1.02 |

||

|

70 |

218 |

212,30 |

16 |

18 |

1.18 |

||

|

80 |

24B |

242.60 |

16 |

18 |

1.50 |

||

K410A

| SPROCKETS | mm |

| Tooth width (T) | 2.8 |

| CHAIN | mm |

| Pitch (P) | 12.70 |

| Internal width | 3.4 |

| Roller Φ (Dr) | 7.75 |

|

Type |

Teeth |

Do |

Dp |

Bored |

Wt kg |

Material |

|

|

Stock |

Min |

||||||

| K410A |

8 |

38 |

33.19 |

10 |

12 |

0.01 |

C45 Solid |

|

9 |

42 |

37.13 |

10 |

12 |

0.02 |

||

|

10 |

46 |

41.10 |

11 |

13 |

0.05 |

||

|

11 |

51 |

45.08 |

12 |

14 |

0.09 |

||

|

12 |

55 |

49.07 |

12 |

14 |

0.10 |

||

|

13 |

59 |

53.07 |

15 |

17 |

0,12 |

||

|

14 |

63 |

57.07 |

15 |

17 |

0.14 |

||

|

IS |

67 |

61.08 |

15 |

17 |

0.16 |

||

|

16 |

71 |

65.10 |

15 |

17 |

0.18 |

||

|

17 |

76 |

69.12 |

15 |

17 |

0.20 |

||

|

18 |

80 |

73.14 |

15 |

17 |

0.23 |

||

|

19 |

84 |

77.16 |

15 |

17 |

0.26 |

||

|

20 |

88 |

81.18 |

16 |

18 |

0.29 |

||

|

21 |

92 |

85.21 |

16 |

18 |

0.30 |

||

|

22 |

96 |

89.24 |

16 |

18 |

0.35 |

||

|

23 |

100 |

93.27 |

16 |

18 |

0.38 |

||

|

24 |

104 |

9730 |

16 |

18 |

0.40 |

||

|

25 |

108 |

101.33 |

16 |

18 |

0.45 |

||

|

26 |

112 |

105.36 |

16 |

18 |

0.49 |

||

|

27 |

116 |

109.40 |

16 |

18 |

0.50 |

||

|

28 |

120 |

113.43 |

16 |

18 |

0.56 |

||

|

29 |

124 |

117.46 |

16 |

18 |

0.60 |

||

|

30 |

128 |

12L50 |

16 |

18 |

0.63 |

||

|

31 |

133 |

125.53 |

16 |

18 |

0.65 |

||

|

32 |

137 |

129.57 |

16 |

18 |

0.70 |

||

|

33 |

141 |

133.61 |

16 |

18 |

0.75 |

||

|

34 |

145 |

137.64 |

16 |

18 |

0.80 |

||

|

35 |

149 |

141.68 |

16 |

18 |

0.85 |

||

|

36 |

153 |

145.72 |

18 |

20 |

0.90 |

||

|

37 |

157 |

149.75 |

18 |

20 |

0.99 |

||

|

38 |

161 |

153.79 |

18 |

20 |

1.00 |

||

|

39 |

165 |

157.83 |

18 |

20 |

1.18 |

||

|

40 |

169 |

161.87 |

18 |

20 |

1.20 |

||

|

41 |

173 |

165.91 |

18 |

20 |

1.20 |

||

|

42 |

177 |

169.94 |

18 |

20 |

1.25 |

||

|

44 |

185 |

178.02 |

18 |

20 |

135 |

||

|

45 |

189 |

182.06 |

18 |

20 |

1.40 |

||

|

46 |

193 |

186.10 |

18 |

20 |

1.49 |

||

|

47 |

197 |

190.14 |

18 |

20 |

1.58 |

||

|

48 |

201 |

194.18 |

18 |

20 |

1.63 |

||

|

49 |

205 |

198.22 |

18 |

20 |

1.73 |

||

|

50 |

209 |

202.26 |

18 |

20 |

1.80 |

||

|

52 |

218 |

210.34 |

18 |

20 |

1.93 |

||

|

54 |

226 |

Z18-42 |

18 |

20 |

2.00 |

||

|

60 |

250 |

242.66 |

18 |

20 |

2.60 |

||

K40A

| SPROCKETS | mm |

| Tooth width (T) | 7.2 |

| CHAIN | mm |

| Pitch (P) | 12.7 |

| Internal width | 7.95 |

| Roller Φ (Dr) | 7.95 |

|

Type |

Teeth |

Do |

Dp |

Bored Stock |

Min |

Wt kg |

Material |

|

K4OA |

10 |

46 |

41.10 |

9.5 |

115 |

0.05 |

C45 Solid |

|

11 |

51 |

45.08 |

10.5 |

12.5 |

0.09 |

||

|

12 |

55 |

49.07 |

11.5 |

13.5 |

0.10 |

||

|

13 |

59 |

53.07 |

13.5 |

15-5 |

0.12 |

||

|

14 |

63 |

57.07 |

13.5 |

15.5 |

0.14 |

||

|

15 |

67 |

61.08 |

13.5 |

15.5 |

0J6 |

||

|

16 |

71 |

65.10 |

13.5 |

15.5 |

0.18 |

||

|

17 |

76 |

69.12 |

13.5 |

15,5 |

0.20 |

||

|

18 |

80 |

73.14 |

13-5 |

15,5 |

0.23 |

||

|

19 |

84 |

77.16 |

13.5 |

15.5 |

0.26 |

||

|

20 |

88 |

81.18 |

14 |

16 |

0.29 |

||

|

21 |

92 |

85.21 |

14 |

16 |

0.30 |

||

|

22 |

96 |

89.24 |

14 |

16 |

0.35 |

||

|

23 |

100 |

93.27 |

14 |

16 |

0.38 |

||

|

24 |

104 |

97.30 |

14 |

16 |

0.40 |

||

|

25 |

108 |

101.33 |

14 |

16 |

0.45 |

||

|

26 |

112 |

105.36 |

14 |

16 |

0.49 |

||

|

27 |

116 |

109.40 |

14 |

16 |

0.50 |

||

|

28 |

120 |

113.43 |

14 |

16 |

0.56 |

||

|

29 |

124 |

117.46 |

14 |

16 |

0.60 |

||

|

30 |

128 |

121.50 |

14 |

16 |

0.63 |

||

|

31 |

133 |

125.53 |

14 |

16 |

0.65 |

||

|

32 |

137 |

129.57 |

14 |

16 |

0.70 |

||

|

33 |

141 |

133.61 |

14 |

16 |

0.75 |

||

|

34 |

145 |

137.64 |

14 |

16 |

0-80 |

||

|

35 |

149 |

141,68 |

14 |

16 |

0.85 |

||

|

36 |

153 |

145.72 |

16 |

18 |

0.90 |

||

|

37 |

157 |

149.75 |

16 |

18 |

0.99 |

||

|

38 |

161 |

153.79 |

16 |

18 |

1.00 |

||

|

39 |

165 |

157.83 |

16 |

18 |

1.15 |

||

|

40 |

169 |

161.87 |

16 |

18 |

1.20 |

||

|

41 |

173 |

165.91 |

16 |

18 |

1.20 |

||

|

42 |

177 |

169.95 |

16 |

18 |

1.25 |

||

|

43 |

181 |

173.98 |

16 |

18 |

1.30 |

||

|

44 |

185 |

178.02 |

16 |

18 |

1.35 |

||

|

45 |

189 |

182.06 |

16 |

18 |

1.40 |

||

|

46 |

193 |

186.10 |

16 |

18 |

1.49 |

||

|

47 |

197 |

190.14 |

16 |

18 |

1.58 |

||

| 48 |

201 |

194.18 |

16 |

18 |

1-63 |

||

|

49 |

205 |

198.22 |

16 |

18 |

1.73 |

||

|

50 |

209 |

202.26 |

16 |

18 |

1.80 |

||

|

51 |

214 |

206.30 |

16 |

18 |

1.88 |

||

|

52 |

218 |

210.34 |

16 |

18 |

1.93 |

||

|

53 |

222 |

214.38 |

16 |

18 |

1.98 |

||

|

54 |

226 |

218.42 |

16 |

18 |

2.00 |

||

|

S5 |

230 |

222.46 |

16 |

18 |

2.18 |

||

|

56 |

234 |

226.50 |

16 |

18 |

2.26 |

||

|

58 |

242 |

234.58 |

16 |

18 |

2.43 |

||

|

59 |

246 |

238.62 |

16 |

18 |

2.51 |

||

|

60 |

250 |

242,66 |

16 |

18 |

2.60 |

||

|

62 |

258 |

250.74 |

16 |

18 |

2.77 |

||

|

64 |

266 |

258.83 |

16 |

18 |

2.90 |

||

|

65 |

270 |

262.87 |

16 |

18 |

3.00 |

||

|

68 |

282 |

274.99 |

16 |

18 |

3.35 |

||

|

70 |

290 |

283.07 |

16 |

18 |

3.50 |

||

|

72 |

299 |

291.16 |

20 |

22 |

370 |

||

|

75 |

311 |

303,28 |

20 |

22 |

4.00 |

||

|

80 |

331 |

323.49 |

20 |

22 |

4.60 |

||

|

85 |

351 |

343.69 |

20 |

22 |

5.20 |

||

|

90 |

371 |

363.90 |

20 |

22 |

5.80 |

Plate wheel:

The plate wheel helps to determine the performance and service life of the chain

Plate wheels help determine the performance and service life of the chain, so GL provides appropriate corresponding plate wheels from its extensive inventory of all chains. This ensures proper alignment between the chain and the plate wheels and prevents fit differences that can affect the overall life of the chain drive. GL also manufactures the sprockets and plate wheels from solid materials or welded material exactly as the customer requires. GL offers a variety of tooth shapes and material options with or without hardened teeth. Designs include simplex, duplex, triplex and cast iron. European standard / AMERICA standard / Asian standard are avilable.

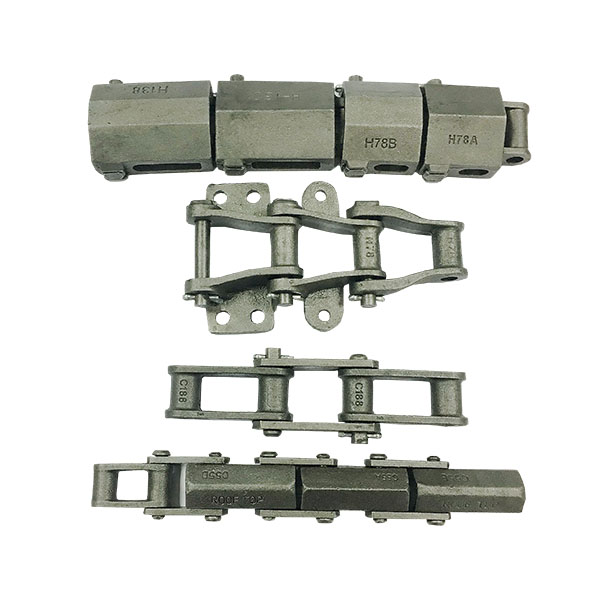

Product detail pictures:

Related Product Guide:

Sticking for the perception of "Creating products of top quality and producing friends with people today from all around the world", we constantly place the desire of shoppers to start with for Professional China Cast Iron Sprockets - Platewheels per Asian Standard – GOODLUCK , The product will supply to all over the world, such as: India, Swedish, Southampton, We follow superior mechanism to process these goods that ensure optimum durability and reliability of the goods. We follow latest effective washing and straightening processes that enable us to supply unmatched quality of items for our clients. We continually strive for perfection and all our efforts are directed towards attaining complete client satisfaction.

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!