Stainless steel chains

-

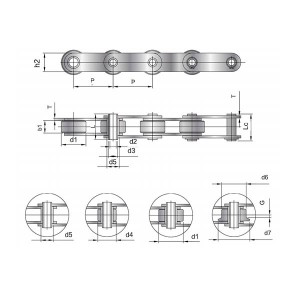

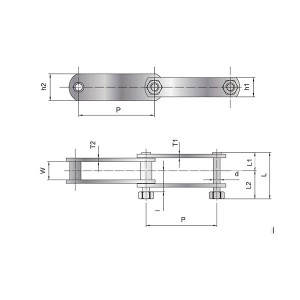

SS FVC Series Conveyor Chains with Different Kinds of Roller with Rollers in SS/POM/PA6

We mainly produced many kinds of chains, such as roller chains, conveyor chains, and agricultural chains etc.FVC Type Hollow Pin Conveyor Chains include P Type Roller, S Type Roller and F Type Roller.

-

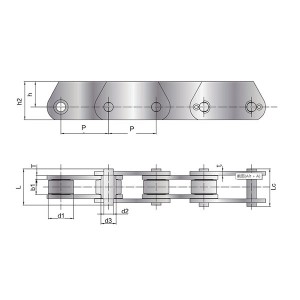

SS Z Series Conveyor Chains with Different Kinds of Roller in SS/POM/PA6

In the context of the transport chain industry, GL supplies a variety of chains according to the standards DIN 8165 and DIN 8167, as well as models in inches manufactured to British standards, and highly diverse special versions. Bushing chains are typically used for long distance conveying tasks at relatively low

-

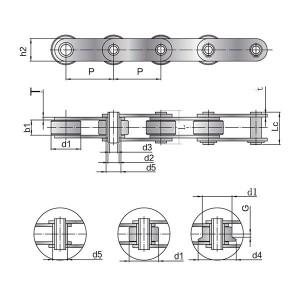

SS ZE Series Conveyor Chains with Rollers in SS,POM, PA6

The offered conveyor long pitch chain is very widely sued for transferring industrial goods from one place to another.With the outside roller diameter smaller than the height of link plate, is used for bucket elevator and flow conveyors.

-

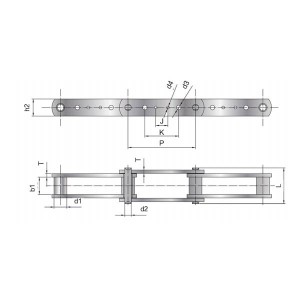

SS ZC Series Conveyor Chains with Different Kinds of Roller in SS,POM, PA6 Rollers

1.Material: 1. 300, 400, 600 stainless steel; 2.Roller material avilable: stainless steel, POM, PA6; 3. Use occasions: environmental protection such as sewage treatment.

-

SS Roller Chains wtih different Kinds of U Type Attachment

We will try our best to create 100% satisfaction and 100% peace of mind for users and try to do our best to meet the needs of customers and create a brilliant tomorrow together! Continuous improvement is our self-discipline.

-

SS Hollow Pin Chains in Short Pitch,or in Double Pitch Straight Plate with Small/Big Roller

GL stainless steel hollow pin roller chain is manufactured in accordance to ISO 606, ANSI,and DIN8187 manufacturing standards. Our hollow pin stainless steel chain is manufactured from high-quality 304-grade stainless steel. 304SS is a highly anti-corrosive material with a very low magnetic pull, its also capable of operating in very low to very high temperatures without degrading the working and performance capacity of the chain.

-

SS Speed Chains with SS/Plastic Roller Suit toDifferent Kinds of Speed

Special structure combining a small diameter roller and a large diameter roller achieves transport with 2.5 times greater speed. Because the chain speed is low, accumulation with low noise is possible.It is widely used in the assembly and assembly automation fields of new energy batteries, auto parts, motors, 3C electronics and home appliances.

-

SS Plastic Chains with Rollers in POM/PA6 Material

Uses SS for the pins and outer links, and special engineering plastic (matte white,POM or PA6) for the inner links, for better corrosion resistance than standard series. However, be advised when selecting that the maximum allowable load is 60% that of standard series chain.

-

SS Top Roller Conveyor Chains for Short Pitch or Double Pitch Straight Plate

All parts use SUS304 equivalent stainless steel for corrosion resistance.

Top rollers available in plastic rollers, stainless steel rollers.

Plastic rollers

Material: Polyacetal (white)

Operating temperature range: -20ºC to 80ºC

Stainless steel rollers -

SS Lumber Conveyor Chains, Type SS3939, SS3939H, SS81X, SS81XH, SS81XHH,SS500R, SS441.100R

Lumber conveyor chain is widely used for wood factory.The main specification includes 81X,81XH,81XHH,and 3939 lumber conveyor chain. Carbon steel material is avilable.

-

SS Flat Top Chains, Type SSC12S, SSC13S, SSC14S, SSC16S, SSC18S, SSC20S, SSC24S,SSC30S

GL Flat Top Chains made of stainless steel are produced in straight running and side flexing versions and the range is covered by a broad selection of raw materials and chain link profiles to provide solutions for all conveying applications. These Flat Top Chains are characterised by high working loads, highly-resistent to wear and extremely flat and smooth conveying surfaces. The chains can be used in many applications and are not just confined to the Beverage Industry.

-

SS HSS HSC SAV Chains, and with Attachments

Working with save type sprocket is the best to get economical merit gained from lighter weight and longer life. It is good to replace plastic chain when customers needs to solve problems by plastic chain, such as extension and wear. You can just remove plastic chain and install SAV chain as you never need to change sprocket.